La technique de lyophilisation par pulvérisation dans la fabrication de produits pharmaceutiques (en anglais)

Certains produits biopharmaceutiques tels que les vaccins ont une courte durée de conservation et doivent être manipulés avec soin. Une récente revue de la littérature présente la technique de lyophilisation par pulvérisation comme option intéressante pour optimiser la fabrication en continu de produits biopharmaceutiques.

The worldwide coronavirus pandemic has revealed the fragility of the pharmaceutical supply chain. The authors of a recent literature review believe that one solution to rapidly address emergencies would be the implementation of continuous manufacturing of biopharmaceuticals. This would provide a more agile and reliable supply chain for both existing and new products. [1] Their article reviews the advantages and challenges of the spray freeze-drying (SFD) technique as a continuous operation.

Principles of Spray Freeze-Drying

Spray freeze-drying (SFD) is a technique that takes advantage of characteristics of spray drying, which involves atomising a liquid to create smaller particles, and freeze-drying, which is of particular value for drying thermally heat-sensitive materials, to create dry powders of controlled size and enhanced stability.

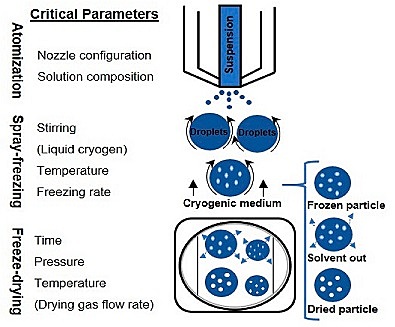

The SFD technique is a three-step operation:

Atomization: The feed solution (composed mainly of an active pharmaceutical ingredient, a solvent and an excipient [2]) is initially sprayed through an atomizer.

Spray-freezing: The atomized droplets are frozen into a spherical droplet shape, by contact with the medium at low-temperature. There are several methods of spray-freezing. The most commonly used in pharmaceutical applications is the atomization of a feed solution into a cryogenic vapour over liquid. In the process, the droplet sprayed from a nozzle positioned at a distance above the boiling cryogenic liquid begins to freeze slowly while falling down through the cold vapour phase before it comes into contact with the cryogen. Finally, the frozen particles in suspension are captured either by sieving, or by allowing the cryogen to evaporate and then transferring them to a freeze-dryer to obtain a dry powder.

Freeze-drying: After cryogenic processing, the frozen droplets are transferred to a freeze-dryer to sublimate the water and obtain a dry powder.

The SFD technique allows a high degree of control over the residual moisture content, mass density, and particle size. Furthermore, it allows easy manipulation of process parameters such as the temperature of the cryogenic liquid, the chemical composition and concentration of the solution, as well as the choice of atomizer type.

Application of Spray Freeze-Drying to Pharmaceutical and Biological Products

Unlike traditional drugs synthesized from chemical processes, the majority of biopharmaceutical products are produced using biotechnology. Biopharmaceuticals (e.g. vaccines, hormones, insulin, etc) consist of sugars, proteins, nucleic acids, living cells or tissues, extracted or semi-synthesized from biological sources. [3] Biopharmaceuticals are large and complex molecules that must be handled with care to maintain their effectiveness. The relatively short shelf life stability of liquid biomolecular drugs, as well as cold chain storage and transport costs, make it necessary to remove water by drying. [1]

The authors of the article believe that the SFD method is ideal for processing proteins, antibodies, vaccines, dry powder aerosols, and nanoparticles since it allows the production of small spherical powders with a relatively size-controlled porous shape. Studies have reported an effective use of SFD to produce dry biomacromolecule powders for specific applications such as pulmonary delivery, microencapsulation, and enhancing the solubility of poorly water-soluble drugs. SFD has also been used to produce microparticles with characteristic morphology and adequate stability by developing particle formulations.

The authors acknowledge the fact that the development of a continuous spray freeze-dryer for pharmaceuticals remains a challenge. Most of the reported SFD technologies have been designed to operate in batch mode. Nevertheless, the authors conclude that some SFD technologies can potentially be converted, with minor modifications, to the continuous production of pharmaceuticals, thus reducing the capital and operational costs associated with long batch cycles, as well as the risk of product contamination, and increasing the uniformity of the final product quality. [1]

Sources

[1] Adali, M.B.; Barresi, A.A.; Boccardo, G.; Pisano, R. Spray Freeze-Drying as a Solution to Continuous Manufacturing of Pharmaceutical Products in Bulk. Processes 2020, 8, 709. https://doi.org/10.3390/pr8060709

[2] Ziaee, A., Albadarin, A. B., Padrela, L., Femmer, T., O'Reilly, E., & Walker, G. (2019). Spray drying of pharmaceuticals and biopharmaceuticals: Critical parameters and experimental process optimization approaches. European Journal of Pharmaceutical Sciences, 127, 300-318. https://doi.org/10.1016/j.ejps.2018.10.026

[3] Yuan-Chuan Chen and Ming-Kung Yeh (September 19th 2018). Introductory Chapter: Biopharmaceuticals, Biopharmaceuticals, Ming-Kung Yeh and Yuan-Chuan Chen, IntechOpen. https://doi.org/10.5772/intechopen.79194