Ready-to-deploy technologies to decarbonise Europe’s refrigerated transport: up to 72% CO₂ savings and 90% reduction in air pollutants

Researchers of the Italian National Research Council, members of IIR D2 Commission (Refrigerated Transport), have estimated the number of refrigerated vehicles currently circulating in Europe and have assessed the potential impact of high technology-readiness-level (TRL) solutions on the reduction of their primary energy consumption and carbon footprint.

As part of the research activities of the recently concluded EU ENOUGH Project, which aimed to provide technical, financial and political tools to achieve the future decarbonisation the European food chain, a team of researchers of the Italian National Research Council (CNR), including Silvia Minetto and Antonio Rossetti, respectively President and Secretary of the IIR D2 Commission (Refrigerated Transport), published an article on the International Journal of Refrigeration [1] where a procedure to estimate the number of vehicles composing the EU refrigerated transport fleet, differentiated by country, is proposed, and the potential positive impact of several high TRL technologies on the reduction of its energy consumption and GHG emissions is evaluated.

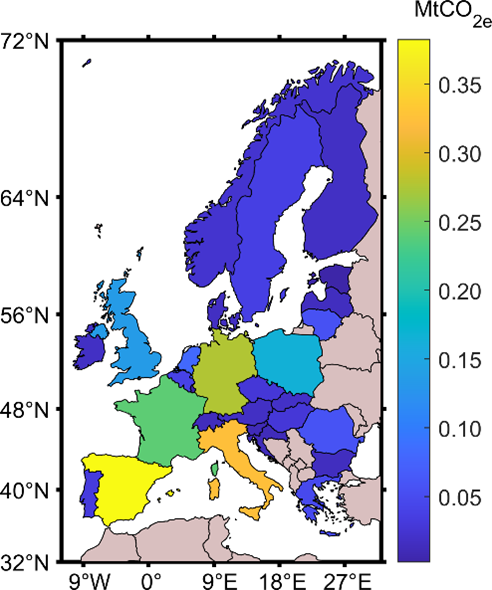

Current size and environmental impact of EU refrigerated fleet

Starting from the number of refrigerated vehicles in service in some countries (Denmark, France, Germany, Italy, Poland, Spain and United Kingdom), collected from different national sources, the CNR researchers extrapolated the number of refrigerated trucks operating in the other EU countries, based on data available on reports and open-source databases, such as the overall capacity of the commercial European fleet (including non-refrigerated transport) [2], the yearly food products transported in each country [3] and the share of chilled and frozen food products sold in each country every year [4]. Following this procedure, the researchers estimated a total number of approximately 945.000 refrigerated vehicles currently employed in EU countries, 42% of which are Light Commercial Vehicles (LCV, up to 3.5 t) and the remaining 58% are Medium, Heavy Commercial Vehicles and Semitrailers (MHCV+S, over 3.5 t).

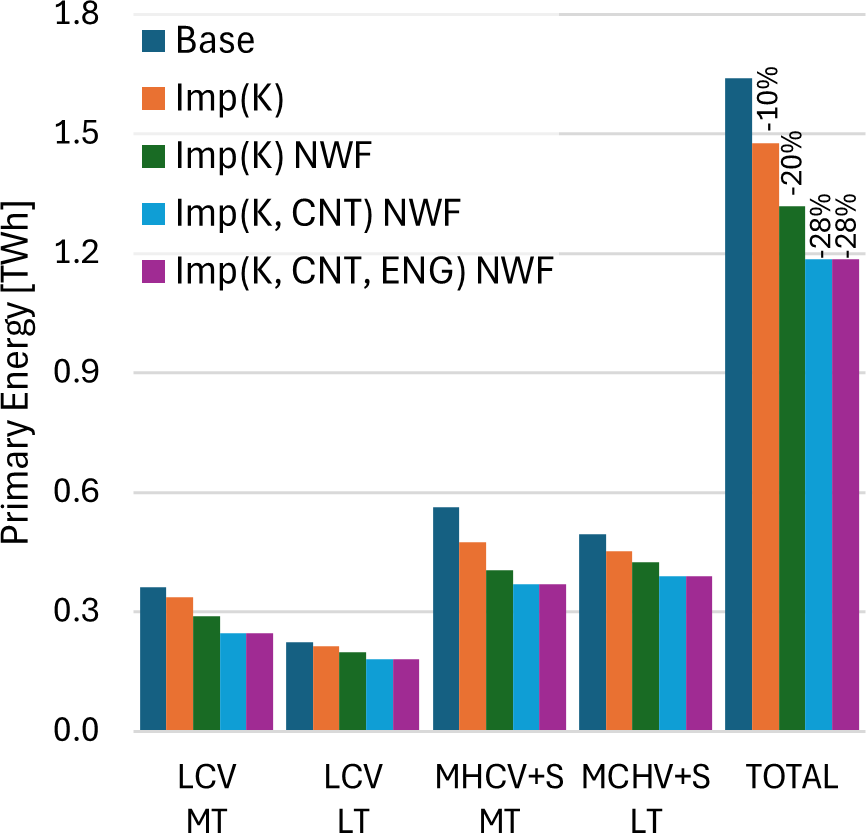

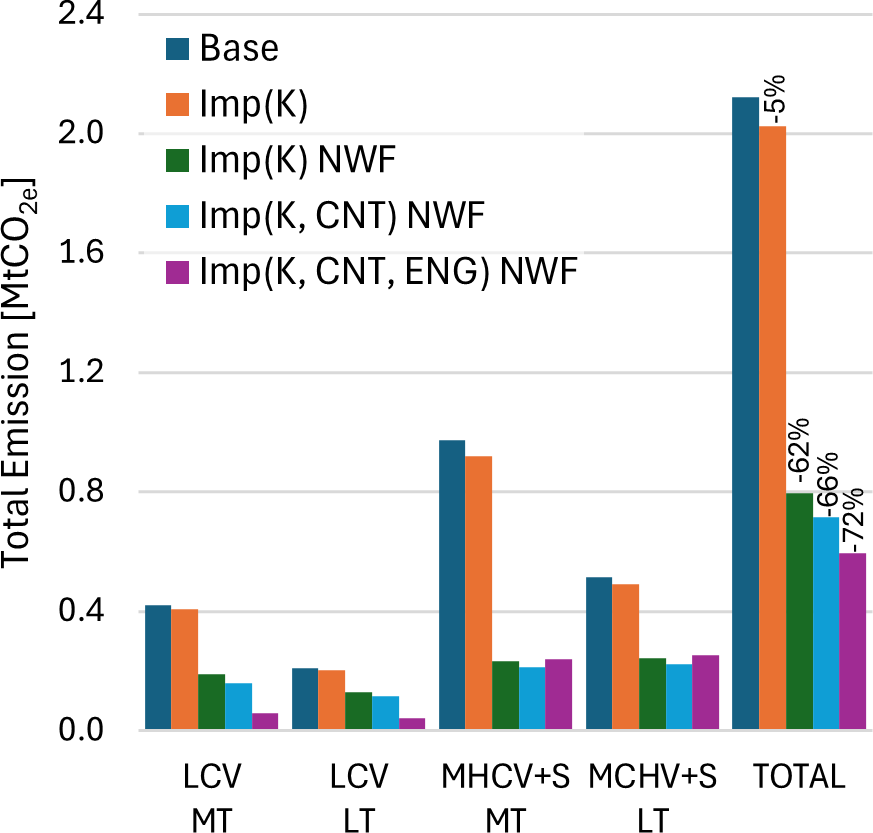

The numerical assessment conducted by the researchers estimated that the EU transport refrigeration fleet, excluding the vehicles traction, is currently responsible for an overall primary energy consumption of approximately 1.6 TWh/year and for a total carbon footprint of approximately 2.1 MtCO2,eq/year.

Potential benefit from ready-to-deploy technologies

The authors then assessed the potential impact of several different solutions, each of them characterized by a high TRL, therefore available for potential implementation in current market:

- Improving the insulation of the refrigerated body containing the products to be transported by lowering its global heat transfer coefficient by 20% compared to the ATP limit can reduce the primary energy demand by 10.1% compared to the baseline reference scenario.

- The use of natural working fluids instead of high GWP synthetic working fluids can add 9.5% energy savings and massively reduce the overall GHG emissions by -57.9%.

- Implementing a variable speed control on the cooling unit compressor, allowing capacity control during operation, and improving the primary energy source utilized by the cooling unit by electrification (for LCV) and with better performing EURO VI engines (for MHCV+S) can contribute with an energy saving of 8.1%, a GHG emissions reduction of 9.5% and a decrease of other pollutants emission (CO, NOx, PM) up to 70.0%.

- The integration of photovoltaic (PV) panels into the insulated box roof can contribute to a reduction in carbon footprint of up to 20.0% compared to the baseline scenario.

Overall, the combined implementation of the considered technologies could lead to a potential reduction of the annual energy consumption of the European fleet up to 28%, corresponding to a saving of equivalent CO2 emissions up to 72%, reducing at the same time also other air pollutants by over 90%.

This study highlights how significant improvements, both in terms of primary energy consumption and environmental sustainability, could be achieved in current refrigerated transport sector by implementing available technologies. Remarkably, such contribution to the increase of efficiency of the EU refrigerated vehicles fleet could be obtained while still maintaining the same commercial volume and number of trucks, demonstrating that environmental sustainability does not necessary imply restrictions and inconveniences for stakeholders, market and consumers.

Annual primary energy consumption (left) and overall carbon footprint (right) of EU road refrigerated transport: current baseline and different improvement scenarios.

For more information, the article is available in open access in the International Journal of Refrigeration and on FRIDOC.

Sources

[1] Rossetti, A., Fabris, F., Marinetti, S., Minetto, S. (2026). The EU road refrigerated transport: current GHG footprint of transport refrigeration unit and projected impact of sustainable technologies. International Journal of Refrigeration 183, 294-305. https://doi.org/10.1016/j.ijrefrig.2026.01.008

[2] European Automobile Manufacturers Association (2025). Report – Vehicles on European roads 2025.

https://www.acea.auto/publication/report-vehicles-on-european-roads-2025/

[3] Eurostat (2024). Road freight transport by type of goods and type of transport (t, tkm) – Reference year 2019.

https://ec.europa.eu/eurostat/databrowser/view/road_go_ta_tg/default/table?lang=en

[4] Eurostat (2019). Sold production, exports and imports – Reference year 2019.

https://ec.europa.eu/eurostat/databrowser/view/ds-059358/legacyMultiFreq/table?lang=en