Revolutionising refrigeration: design and optimisation of a rotary magnetic domestic refrigerator

The International Institute of Refrigeration is pleased to highlight a study that advances the field of solid-state refrigeration. Researchers from the University of Genoa, Italy, have developed and optimised a new rotary magnetic refrigerator designed for domestic use at room temperature, offering a promising alternative to traditional vapour-compression systems.

Traditional refrigeration systems rely on high-energy consumption and environmentally harmful refrigerants. In contrast, magnetic refrigeration uses solid-state materials with zero global warming potential (GWP), leveraging the magnetocaloric effect, a temperature change induced by a magnetic field. This technology offers:

- High energy efficiency

- Low environmental impact

- Durability and compact design

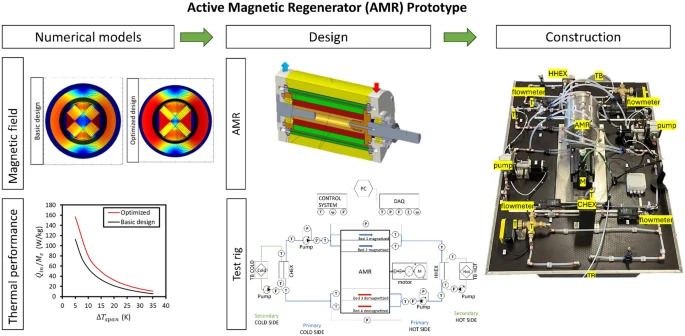

The research team adopted an interdisciplinary approach combining mechanical, thermo-hydraulic, and magnetic design, supported by advanced numerical simulations. Highlights include:

- Rotary design: The device uses a rotary active magnetic regenerator (AMR), enabling smoother operation and higher efficiency than reciprocating systems.

- Optimised magnet circuit: A new magnet configuration enhances magnetic field strength and uniformity, improving cooling performance.

- Modular MCM cartridges: The regenerator features interchangeable cartridges made via 3D printing, allowing easy replacement of magnetocaloric materials (MCMs) like gadolinium.

- Smart control strategy: Optimal rotation frequency and fluid flow rates are determined to maximise cooling load across various temperature spans.

The newly developed rotary magnetic refrigerator demonstrated a significant performance improvement, with the cooling load increasing by over 40% compared to the basic design. Specifically, the optimised system achieved a cooling load of 118.59 watts at a temperature span of 15 K. Additionally, the cooling load-to-magnetocaloric material (MCM) mass ratio improved from 33.24 W/kg to 49.22 W/kg. These gains were supported by enhancements in magnet flux density and reductions in dead volume losses, contributing to the overall efficiency of the device.

While gadolinium (Gd) remains a highly effective MCM, its cost and environmental footprint pose challenges for large-scale implementation. To address these concerns, the study proposes several practical solutions: utilising 3D printing to reduce material waste and fabrication costs, exploring alternative magnetocaloric materials with improved sustainability profiles, and integrating artificial intelligence-based control systems to further optimise performance.

The prototype has been successfully constructed and integrated into a test rig for experimental validation. Future research will focus on evaluating real-world performance, scaling the technology for commercial applications, and reducing reliance on rare-earth materials to enhance environmental sustainability and economic feasibility.

This study marks a significant step toward sustainable refrigeration technologies. By combining innovative design with practical engineering, the rotary magnetic refrigerator offers a viable path to low-carbon cooling solutions.

Access the full article here: https://link.springer.com/article/10.1007/s10098-024-02900-4

Did you know? IIR has a working group dedicated to promoting international research collaboration in the areas of solid-state cooling, heat pumps, and energy harvesting.