IIR Cryogenics 2025 conference: Using Waste Cold Energy from Liquid Hydrogen to Save Energy on Nitrogen Liquefaction

F. Herzog et al. proposed recovering waste cold energy from liquid hydrogen production to help produce liquid nitrogen, thus saving energy on N2 liquefaction, while reducing the heat requirement for the regasification of hydrogen.

Air separation by cryogenic distillation is a mature technology for the mass production of air products like oxygen and nitrogen, which are used in a broad range of industrial applications. For instance, liquid nitrogen is widely used in the food and beverage industry, from food processing to refrigerated transport in cryogenically cooled trucks [1]. Following separation, the gas is liquefied to allow cost effective delivery. As a result, production of liquid nitrogen results in carbon emissions [2].

In a communication presented during the last IIR Cryogenics conference held in Prague, Czech Republic on April 7-11, 2025, F. Herzog et al. proposed recovering waste cold energy from liquid hydrogen production to help produce liquid nitrogen (or oxygen) [3].

Liquefied hydrogen is stored in terminals at a temperature of –253 °C (20 K). When needed, the liquid hydrogen is withdrawn from the storage vessels, pressurised with cryogenic pumps, regasified using heat and then fed into a pipeline network. The cold of the liquid hydrogen is wasted.

Meanwhile, nitrogen is separated from the air in a standard air separation plant and then liquefied. The cold energy from a liquid hydrogen terminal could contribute to increasing the efficiency of the air separation process. However, F. Herzog et al. propose that the cold energy be used primarily for the liquefaction of nitrogen, the process with the highest energy requirement. The nitrogen condensation could then take place practically without the addition of external energy.

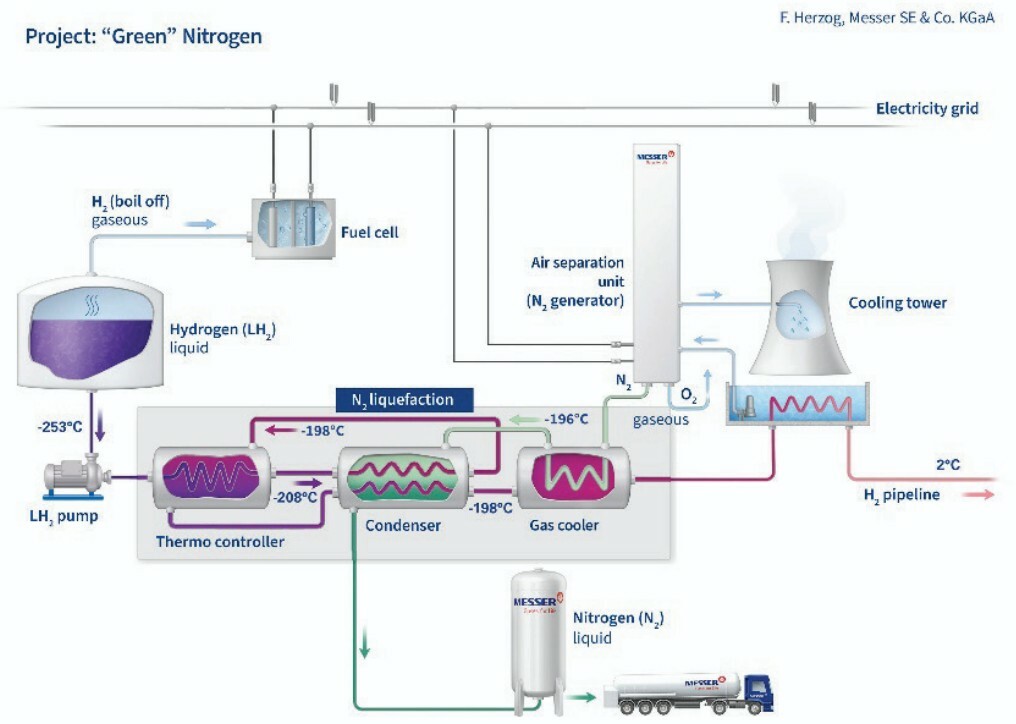

Figure 1 describes the main components of such an installation. A plant for producing so-called “green” liquid nitrogen essentially consists of a conventional air separation plant, a liquid hydrogen terminal and the equipment for N2 liquefaction.

The liquid hydrogen from the tank is first increased to the required gas network feed pressure (e.g. 80 bar) using a pump. Instead of the regasification heat exchanger that normally follows, the N2 liquefaction devices are then installed.

Significant energy savings can be achieved in the production of liquid nitrogen (or oxygen), while also reducing the heat requirement for the regasification of hydrogen.

If hydrogen is to be stored in a liquid form and then used in a gaseous or supercritical state, the valuable hydrogen cold can be used to liquefy nitrogen (or oxygen) or operate more energy efficient cryogenic air separation plants. When separating the air components, around 3% to 4% of electrical energy can be saved. During liquefaction, hydrogen refrigeration can serve as the only process energy source (100% savings).

According to the authors, if hydrogen cold is fully utilised, no energy is required for regasification. With a hydrogen throughput of 1,000 kg/h, this leads to heat savings of around 1,000 kW.

Find out more in the paper available on FRIDOC

Production of “green” nitrogen with liquid hydrogen.

Sources

[1] Baha M., Hammami S., Dupont J.-L. The role of refrigeration in global economy. 3rd edition. 60th Technical Brief on Refrigeration Technologies. International Institute of Refrigeration (IIR), Paris. http://dx.doi.org/10.18462/iir.TechBrief.04.2025

[3] Herzog F., Schlotmann A., Corvay S., Evison T. Production of “green” nitrogen with liquid hydrogen. Cryogenics 2025. Proceedings of the 18th IIR International Conference on Cryogenics, Prague, Czech Republic, 7-11 April 2025. https://iifiir.org/en/fridoc/production-of-green-nitrogen-with-liquid-hydrogen-150578

Credits image for illustration purposes: Air Liquide Las Vegas H2 plant