Industry-led project achieves 98% methane slip reduction from LNG-fuelled vessels

In October 2025 a consortium of industry partners achieved a 98% methane slip reduction rate in real-world conditions by combining methane oxidation catalysts with engine improvements.

In the efforts to decarbonise maritime transport, LNG is considered an efficient alternative to conventional fuels (e.g. gasoline, diesel, LPG). However, when using LNG as a fuel, there is still a risk of fugitive methane emissions due to leakages and slips resulting from the incomplete combustion of fuel in engines.

According to IIR member Det Norske Veritas (DNV) [1], achieving complete combustion of LNG in current engines remains a challenge and methane slips can account for up to 24% of GHG emissions from an LNG-fuelled vessel.

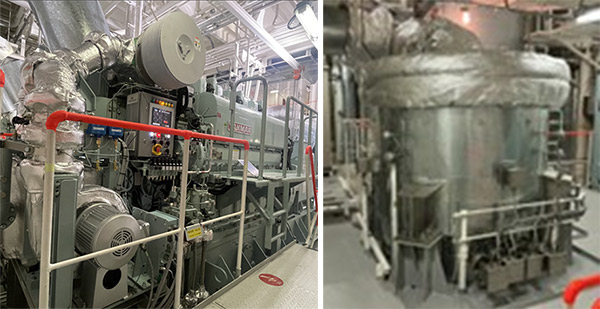

In October 2025, a breakthrough in methane slip reduction technology was announced by a consortium of industry partners – Kanadevia Corporation, Mitsui O.S.K. Lines (MOL), and Yanmar Power Solutions – working on working on a project titled “Development of Methane Slip Reduction Technology for LNG-Fueled Vessels through Catalyst and Engine Improvements” [2].

The six-year project, to be concluded in 2026, aims to achieve a methane slip reduction rate of 70% or more for LNG-fuelled vessels by combining methane oxidation catalysts with engine improvements.

Full-scale demonstration trials conducted since May 2025 have achieved a 98% methane slip reduction rate in real-world conditions, exceeding their initial 70% target. The trials are being conducted on an LNG-fuelled coal carrier on routes between Japan and Australia.

The EGR system is a technology that recirculates engine exhaust gases to reduce unburned methane slip, NOx, and other emissions.

Sources

[1] DNV. Methane slip measurements to reduce reported GHG emissions. 20 March 2025 https://www.dnv.com/news/2025/methane-slip-measurements-to-reduce-reported-ghg-emissions/

[2] Mitsui O.S.K. Lines (MOL) https://www.mol.co.jp/en/pr/2025/25078.html