R1234yf as a working fluid in Organic Rankine Cycle systems

A recent review article presented the use of HFO R1234yf and its mixtures in Organic Rankine Cycle (ORC) systems, namely in applications for waste heat recovery from internal combustion engines.

R1234yf is a low-GWP HFO with similar toxicity and thermodynamic properties to R134a, along with a minimal lifetime in the atmosphere. R1234yf has a lower flammability index which allows for safer operating conditions. R1234yf also has a lower critical temperature (368 K) than fluids commonly used in Organic Rankine Cycle (ORC) systems (such as R134a, R141b, R152a, R245fa, R600, R600a, R1234ze(E)). R1234yf is therefore considered a potential replacement candidate for HFCs in ORC applications.

According to a recent review article, R1234yf and its mixtures are the most energy efficient when used in ORC systems operating in the low-temperature range as the heat source. [1] Studies have concluded that redesigning or adding components to the ORC configuration, such as preheaters, reheaters, or internal heat exchangers, helped improve thermal efficiency and power output. Furthermore, the properties of R1234yf have resulted in improved thermal performance.

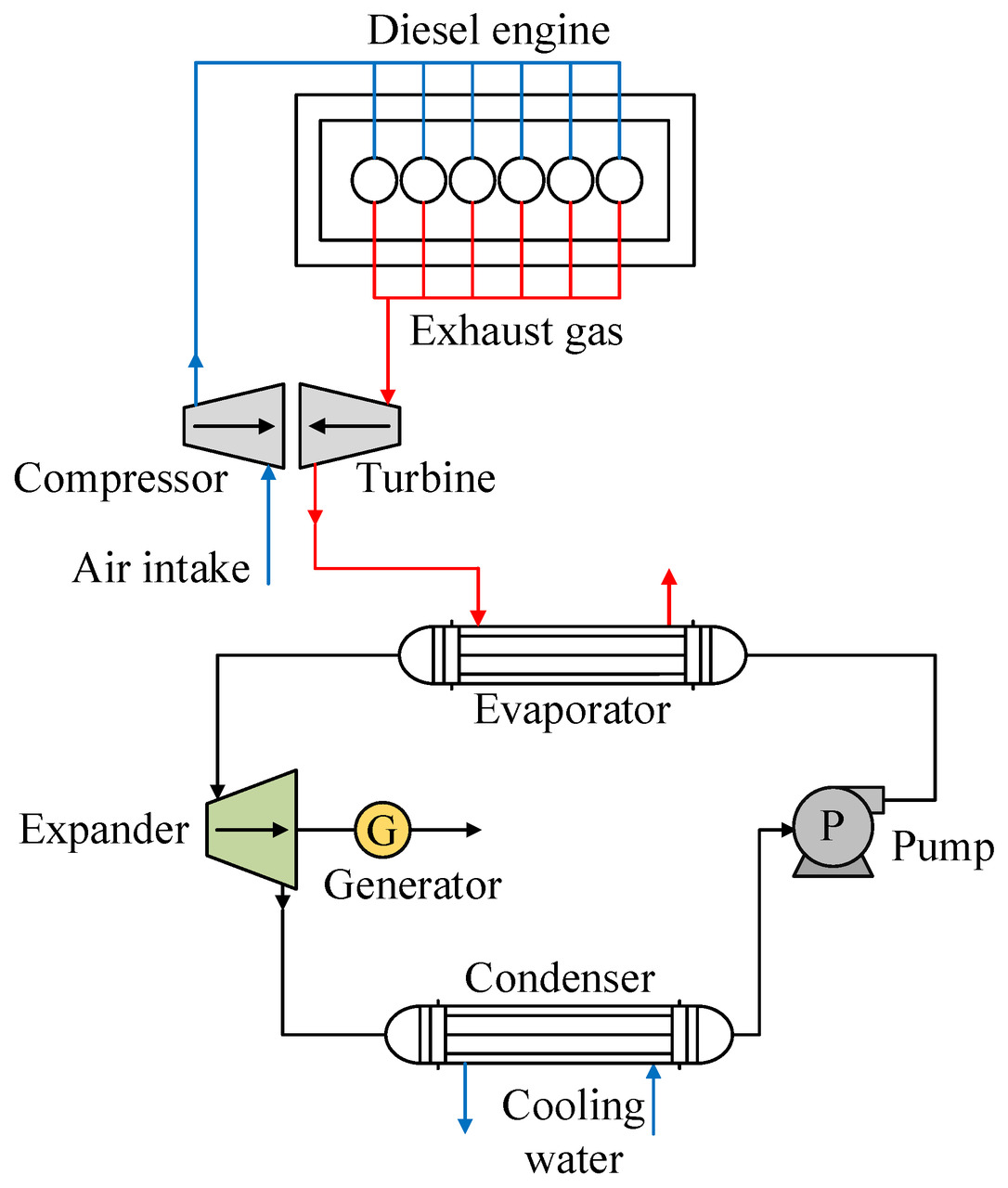

According to the authors of the review article, ORC systems based on the recovery of residual energy from internal combustion engines represent a major research focus in terms of the performance of R1234yf. Indeed, in conventional vehicles, only about 40% of the fuel’s energy is converted into useful energy for driving a vehicle, while the remaining 60% is wasted in the exhaust gases and in the engine cooling system. The waste heat from the exhaust gases reaches temperatures over 200°C, while that from the cooling system is in the range of 80 to 120°C. ORC systems adapted for waste heat recovery are therefore a promising technology, offering high efficiency with simple setup.

In one study, an ORC was thermoeconomically optimised for heat recovery from a diesel engine for marine applications. [2] Under optimal operating conditions and a turbine inlet temperature of 110°C, R1234yf performed better than the other fluids analysed (R1234ze, R152a, R600a and R245fa). The net power generated was 320.3 kW, with a thermal efficiency of 9.45%, which was the highest. For the pressure range of 0.4 to 3 MPa, R1234yf offered the highest output power values. However, the operating costs under such conditions were higher for R1234yf than for the other fluids.

Indeed, in ORC systems for the recovery of residual heat from internal combustion engines, heat exchangers require higher investment costs, especially when additional equipment is included (such as preheaters, internal heat exchangers and reheaters).

There has been limited research on other ORC systems based on geothermal or solar energy. In the few studies on the use of geothermal energy in ORC systems using R1234yf, it showed the best energy performance compared to other environmentally friendly refrigerants, as well as greater energy production, especially when reheaters were included. Concerning studies on the use of solar energy in ORC systems, the use of R1234yf and its mixtures often produced unfavourable results in terms of performance.

- For further information on Rankine cycle systems, papers from the IIR 2020 Rankine conference are available for download on FRIDOC:

Sources

[1] García-Pabón JJ, Méndez-Méndez D, Belman-Flores JM, Barroso-Maldonado JM, Khosravi A. A Review of Recent Research on the Use of R1234yf as an Environmentally Friendly Fluid in the Organic Rankine Cycle. Sustainability. 2021; 13(11):5864. https://doi.org/10.3390/su13115864

[2] Yang M-H, Yeh R-H. Thermo-economic optimization of an organic Rankine cycle system for large marine diesel engine waste heat recovery. Energy 2015, 82, 256–268. https://doi.org/10.1016/j.energy.2015.01.036