Reducing the environmental impact of ultra-low temperature refrigeration systems

Ultra-low temperature (ULT) refrigeration systems often use very high-GWP HFCs. Yet, ULT systems are excluded from the scope of the regulations aimed at phasing-down HFCs. An IJR paper reviews the most promising low-GWP refrigerants alternatives for ULT refrigeration.

Introduction

Equipment delivering temperatures below –50 °C and down to –100 °C can be defined as ultralow-temperature (ULT) refrigeration. It includes for instance freeze-drying as well as cooling in pharmaceutical, chemical and petrochemical industry.

The EU F-Gas Regulation, the Kigali Amendment to the Montreal Protocol on Substances that Deplete the Ozone Layer as well as regulations by the US Environmental Protection Agency all limit GWP in most types of refrigeration, air-conditioning and heat pump equipment.

However, as the authors of a recent review article [1] in the International Journal of Refrigeration point out, so far, ULT refrigeration has been excluded from regulations especially because there are few units in operation compared to refrigeration systems at temperatures above -50°C. Consequently, there is a paucity of available research and development on ULT refrigeration.

The exclusion of ULT refrigerants from HFC transition policies may explain why few scientific articles have reviewed environmentally friendly alternatives to HFCs for ULT refrigeration. ULT refrigeration commonly uses very high GWP refrigerants such as R23 (GWP of 12,690) and R508B (GWP of 12,000). Therefore it is essential that low-GWP alternative refrigerants are developed in this refrigeration sector. Likewise, the energy efficiency of ULT refrigeration systems needs to be improved.

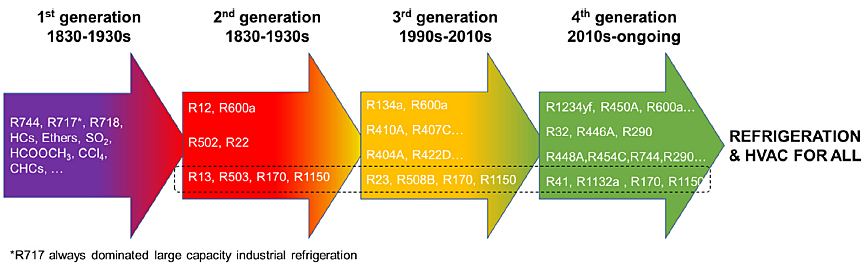

The figure below shows the successive generations of refrigerants used in ULT refrigeration:

System configurations for ULT refrigeration

The most common architecture for ULT refrigeration is the two-stage cascade cycle. Such architecture uses two different refrigerants coupled by a heat exchanger. The heat exchanger acts as an evaporator for the high stage refrigerant and as a condenser for the low stage refrigerant.

Studies suggest that in a cascade cycle with R23 in the low stage, the best refrigerant for the high stage is R717 (ammonia), compared to R290, R404A and R507.

A multi-objective optimization of a cascade refrigeration system has shown that the utilization of hydrocarbons (HCs) was detrimental for safer operation compared to the toxic R717. Therefore, most cascade refrigeration systems for low-temperature refrigeration usually use R744 (carbon dioxide)/R717. However, analysis of optimum thermodynamic parameters for R744/R717 cascade system has revealed that using R1234yf instead of R717 reduces the operating cost while increasing the second law efficiency.

Another architecture for ULT refrigeration is the auto-cascade system, sometimes used in small capacity packaged ULT refrigeration systems. ULT refrigeration can also be achieved in solid-gas sublimation cycles using in particular R744.

Low-GWP alternative refrigerants

A review of studies on ULT refrigeration over the past twenty years indicate that the next generation of refrigerants chosen for ULT refrigeration will be based on low-GWP refrigerants such as R41 (GWP of 116), R1132a (GWP˂1), R170 (ethane, GWP of 5.5) and R1150 (ethylene, GWP of 4).

For ULT systems, the transition to lower GWP refrigerants will depend on the application and the possibility of utilizing refrigerants with some degree of flammability. For ULT refrigeration systems which allow highly flammable refrigerants, readily available HCs may be used, with proper adaptation of the systems. For ULT refrigeration systems which do not allow highly flammable refrigerants, no conventional or direct solution exist.

Natural refrigerants alternatives for ULT refrigeration

R170 and R1150 are HCs with properties that appear suitable for ULT refrigeration systems. Normal boiling point values of R170 and R1150 are −88.6°C and −103.8°C, respectively. Therefore, they can be utilized either in the low stage of cascade ULT refrigeration systems, or as a component in mixed refrigerants for auto-cascade systems. R170 is classified as a flammable cryogenic fluid, recommended for sealed hermetic low-temperature applications.

A study proposed a R290 (propane)/R170 cascade to replace R22/R23, due to the comparable coefficient of performance (COP), especially at lower condensing and evaporating temperature conditions. Moreover, the lower mass flow ratio of the R290/R170 cascade allows a reduction in flammability risk.

Theoretical analysis and intermediate temperature optimization of a cascade system was conducted using R170 and R1150 in the low stage. Compared to other selected refrigerants, R170 had superior performance in terms of COP but not regarding volumetric cooling capacity compared to R744A (nitrous oxide). Nevertheless, its very low GWP favours it. It is worth mentioning that the internal heat exchanger considerably favours R170.

A typically cited drawback of HCs is their high flammability. Some mixtures have thus been examined in order to address this issue.

The azeotropic mixtures of R170/R23, R170/R116 and R170/R23/R116 were investigated in the low stage of a cascade system and compared to R508B while using R404A in the high stage. COP of the R170/R116 mixture was up to 10% higher than that of R508B, but R170/R23/R116 mixture had the highest cooling capacity. The azeotropic mixture of R290/R170 has also been proposed for ULT applications.

The R744/R744A refrigerant mixture was recently studied for applications in which R170 and R1150 cannot be used. A prototype designed with different lubricants made it possible to show that the energy efficiency was comparable to commercially available HFC systems at evaporation temperatures down to −80 °C.

Synthetic refrigerants alternatives for ULT refrigeration

In 2018, a study presented R1132a as an alternative refrigerant in ULT refrigeration systems. R1132a belongs to the family of HFOs which are significantly more stable than other fluorinated ethenes.

Thus, R1132a is proposed for ULT refrigeration as a component of blends with low normal boiling point. For instance, R1132a/R170 binary mixture exhibits larger cooling capacity and COP (at −85 °C evaporating temperature) than pure R170, R508B or R1132a blended with R116.

Another refrigerant that has appeared as an alternative in ULT refrigeration is R41.

Theoretical analysis of R41 as a substitute for R23 in the low stage of a cascade system (with R404A in the high stage) proved higher COP values. However, compared to R170, the COP results were lower, while the power consumption and exergy losses were higher. Considering a three-stage cascade system, R41 and R170 were recommended to replace R23 in the intermediate stage, with R1150 in the low-temperature stage at evaporating temperatures down to −120 °C.

R41 flammability is problematic for its utilization in ULT refrigeration. Mixing R41 with other non-flammable refrigerants, as for instance R744, allows operation in high ambient temperatures while avoiding solid formations, excessive pressures and pressure ratios. R41/R744 (50/50 wt.%) is a potentially non-flammable azeotropic mixture that maximizes the critical temperature and matches the saturated pressure- temperature characteristics and refrigerating capacity of existing refrigerants within this range.

Conclusion

Among hydrocarbon refrigerants, R170 and R1150 are currently the best options as low-GWP alternative refrigerants in ULT refrigeration systems. The issue of their flammability can be addressed by combining them with lower or non-flammable refrigerants in the high stage of cascade systems.

R1132a, a lower-flammability HFO, has been recently considered but the available information is still mainly limited to the characterization of its thermodynamic properties.

R41 is another possible refrigerant but presents some limitations, especially in terms of flammability.

All these alternative refrigerants have presented promising energy results in theoretical simulations in advanced ULT refrigeration configurations. However, additional experimental research is needed to characterize their behaviour and allow them to reliably dominate the market.

[1] Mota-Babiloni, A., Joybari, M. M., Navarro-Esbrí, J., Mateu-Royo, C., Barragán-Cervera, Á., Amat-Albuixech, M., & Molés, F. (2019). Ultralow-temperature refrigeration systems: Configurations and refrigerants to reduce the environmental impact. International Journal of Refrigeration.

https://doi.org/10.1016/j.ijrefrig.2019.11.016