The life cycle of fluorocarbons: case studies

The Climate and Clean Air Coalition has published a guide for policymakers in which good practices regarding the life cycle of fluorocarbons are discussed. Concrete examples of refrigerant recycling in different countries are listed.

The Climate and Clean Air Coalition* (CCAC) has recently published a best practice guide for decision-makers. It is the result of the Initiative on Fluorocarbons Life Cycle Management (IFL) launched at COP25 in 2021 by Japan.

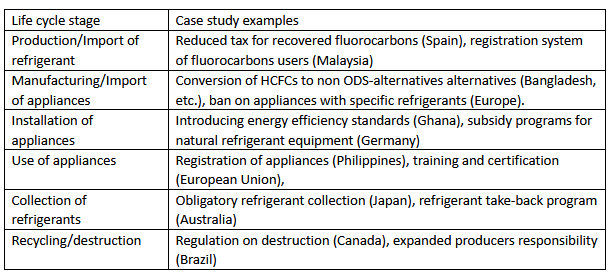

The objective of the guide is to encourage appropriate treatment of fluorocarbons before and after their use. It presents examples of policy measures taken in different countries to manage the life cycle of these substances at different stages: production, import, installation, maintenance, recovery, recycling and/or destruction.

22 cases are studied in the guide, according to the life cycle stage of fluorocarbons.

Focus on the recovery, recycling and destruction of refrigerants.

Several examples of end-of-life management of refrigerants are cited. Here are some of them:

In Japan, refrigerant recovery is mandatory. At the end of life of a device containing a refrigerant gas, it must be recovered by a collector mandated by the owner of the device, whether commercial or domestic. Operators then transfer the refrigerants for recycling or destruction. A certain number of documents allow the refrigerant to be traced during its destruction.

In Denmark, a deposit system has been in place since 1992. Device users must pay a deposit of 27 Danish Krones per kilo of refrigerant, and they receive a reimbursement of 10 krones for recycling, and 5 krones for destruction. .

Of the 27 krone deposit, 22 are transferred to the environmental program of the Danish refrigerant industry, which helps to cover the costs of recycling and/or destruction of refrigerants.

Canada implemented a series of laws to control the import, export, manufacture, sale and certain uses of fluorinated gases in 1998, and amended this law in 2016 to follow the recommendations of the Kigali Amendment to the Montreal Protocol. These controls include the phasing out of ozone-depleting substances (ODS), the requirement to obtain written authorizations for certain activities, and the requirement to report on the export, import or manufacture of ODS. As far as HFCs are concerned, the regulations require a permit for their import, export or manufacture. The regulations also require the destruction of HCFCs or HFCs that are no longer used.

In Colombia, a voluntary producer responsibility scheme has been put in place. It is the duty of the producer (manufacturer or importer) to design and implement the environmental management of devices throughout their life cycle. Producers therefore retain a degree of responsibility for their products throughout their life, from the extraction of raw materials to final disposal.

The Red Verde program supports recovery of devices at end of life. Voluntary financial contributions come from manufacturers and importers. End users can either deliver their old refrigerators to collection points or hire a collection service.

All case studies are available in the document in FRIDOC.

* The Climate and Clean Air Coalition was founded in 2012 by the United Nations Program and several governments (Bangladesh, Canada, Ghana, Mexico, Sweden, United States).

Sources:

https://www.ccacoalition.org/en/file/8673/download?token=XManLIF5