Isochoric freezing could cut down energy use in the global food cold chain

Compared to conventional isobaric freezing, isochoric freezing could significantly improve the quality of frozen food and generate substantial energy savings.

Isochoric freezing was first developed in 2005 by Pr. Boris Rubinsky and his team at the University of California at Berkeley and has been used mainly for the cryopreservation of cells, tissues, and organ transplantation. The potential benefits of isochoric freezing in the food industry were examined much later, through a collaboration with the U.S. Department of Agriculture in 2017. [1]

Isochoric freezing of food products [1- 3]

With conventional freezing at a constant atmospheric pressure (isobaric), the food product is subjected to temperatures of -10°C or colder and a high proportion of the freezable water in the product – usually more than 80% of the water content – is converted to ice. [2] With isochoric freezing, the food product is immersed in an isotonic solution inside a closed chamber, so that the volume remains constant during freezing. As the chamber is cooled down to a preset temperature, the isotonic solution protects the food product from ice crystallisation and better preserves its qualities.

Energy savings for the global food cold chain using isochoric freezing [3-4]

In the conventional food cold chain, storing foods under freezing temperature is an energy-intensive process. Isochoric storage can reduce energy expenditure to an industrial level as no ice formation takes place inside the food. [4]

Most commercial cold storage systems use storage temperatures between – 10 °C and –18 °C. Isochoric storage does not require storage temperatures that low and previous experiments have shown that − 5 °C may be an optimal temperature for isochoric cold storage. According to a recent theoretical study, switching the global food cold chain from conventional isobaric conditions to isochoric freezing conditions could significantly reduce energy use and CO2 emissions.

In the United States, the authors found that compared to isobaric freezing at −18 °C, isochoric cold storage at – 5 °C could save 148 million kWh of electricity annually (equivalent to 19.28 million USD) while reducing emissions of CO2 by 104.87 million kg.

At a global scale, if the total frozen food capacity (estimated at about 31.3 billion kg in 2019) were processed under isochoric conditions at – 5 °C rather than isobaric conditions at the industry-standard of –18 °C, energy use could be reduced by as much as 6.49 billion kWh each year (equivalent to 843.33 million USD in annual savings) while reducing CO2 emissions by 4.59 billion kg annually.

Challenges of isochoric freezing of food products [1,4, 5]

The equipment needed for isochoric freezing is neither complicated nor expensive and the chambers can be placed in conventional freezers in industrial settings or even homes. The processing chambers can be made of thick-walled stainless steel, plastic, or carbon fibre composites, provided that the walls are rigid. [5] Further theoretical and experimental studies are needed to explain the super-cooling stability of isochoric systems by considering varying chamber rigidity ranges. [4]

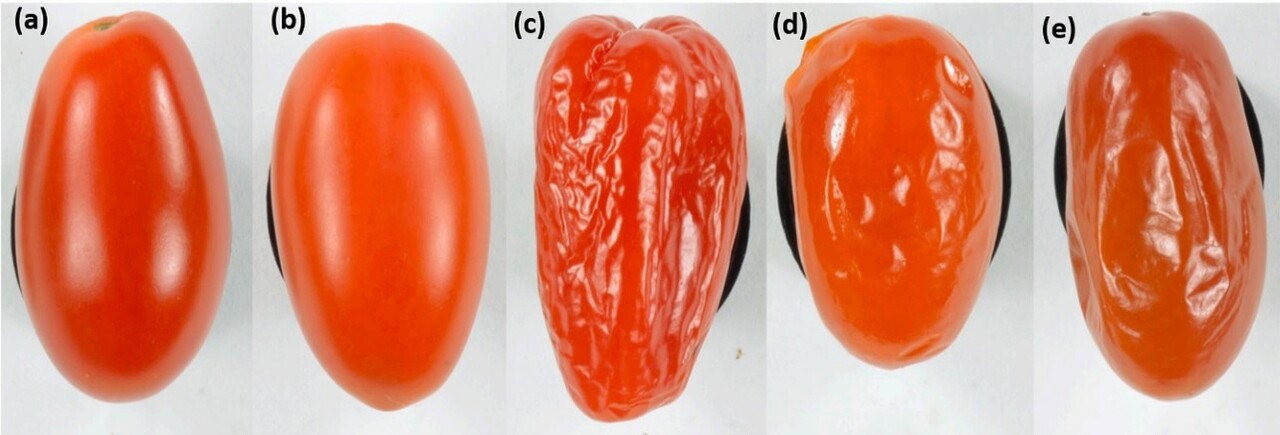

The main disadvantage of isochoric freezing is the generation of hydrostatic pressures inside the processing chamber. Hydrostatic pressure can break the cellular tissues in food products and deteriorate their quality. [1] Optimised protocols for temperature and pressure combination are therefore required for food freezing applications. [4]

Sources

[1] Isochoric Freezing: A New Technology for Food Preservation. https://www.ift.org/news-and-publications/food-technology-magazine/issues/2019/november/columns/isochoric-freezing

[2] IIF-IIR, BØGH-SØRENSEN L. Recommendations for the Processing and Handling of Frozen Foods. https://iifiir.org/en/fridoc/recommendations-for-the-processing-and-handling-of-frozen-foods-4097

[3] Zhao, Y., Powell-Palm, M. J., Wang, J., Bilbao-Sainz, C., McHugh, T., & Rubinsky, B. (2021). Analysis of global energy savings in the frozen food industry made possible by transitioning from conventional isobaric freezing to isochoric freezing. Renewable and Sustainable Energy Reviews, 151, 111621. https://doi.org/10.1016/j.rser.2021.111621

[4] Nida, S., Moses, J. A., & Anandharamakrishnan, C. (2021). Isochoric Freezing and Its Emerging Applications in Food Preservation. Food Engineering Reviews, 1-10. https://doi.org/10.1007/s12393-021-09284-x

[5] Low-energy freezing technology keeps food fresh without forming ice. https://newatlas.com/science/low-energy-isochoric-freezing-food-fresh-ice/