Smart cold storage cuts food loss and energy use with digital twins and IoT sensors

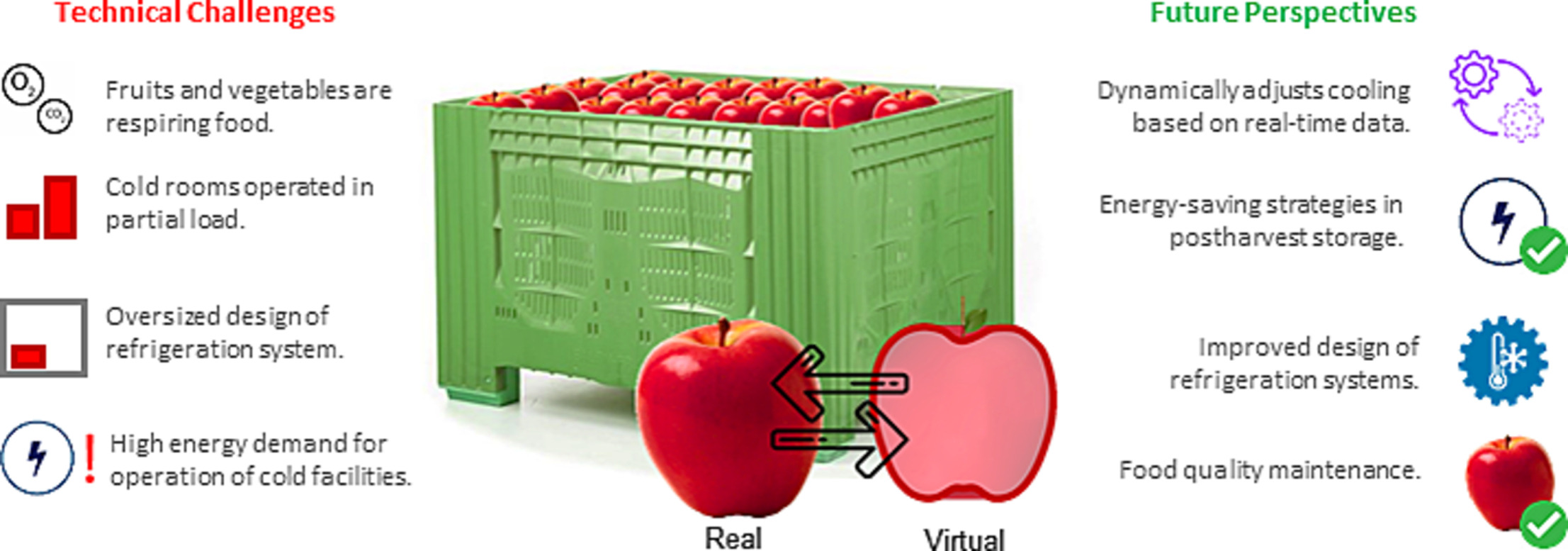

A recent review published in Food Research International highlights how emerging technologies such as digital twins, IoT sensors, and AI-driven monitoring systems are transforming postharvest cold storage, improving produce quality and reducing food loss and energy consumption.

The study was conducted by researchers from several leading institutions, including the Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB) in Potsdam, Humboldt University of Berlin, University of Blumenau (FURB) in Brazil, Lake of Constance Research Center for Fruit Cultivation (KOB), University of Hohenheim, and University of Bremen.

The review identifies temperature and humidity control as critical factors in preserving the quality of fruits and vegetables. Improper storage conditions can lead to spoilage, chilling injuries, and reduced market value. For example, apples stored at ambient temperatures can lose up to 18.2% of their weight, while those kept at optimal cold conditions show significantly lower losses.

To combat these issues, the integration of digital twin technology, virtual models of physical cold storage systems, enables predictive maintenance and dynamic adjustment of cooling parameters. Combined with IoT sensors, these systems allow for real-time tracking of temperature, humidity, airflow, and gas composition, ensuring optimal storage conditions and reducing operational costs.

The study also highlights industrial innovations such as:

- HD Cold Chambers (France): Maintain high humidity without condensation.

- Dry Misting (Netherlands): Enhances humidity and cooling without wetting produce.

- CoolBot Pro (USA): Converts standard air conditioners into cold storage units.

- Solar-Powered Mobile Cold Storage (Kenya): Provides off-grid refrigeration for smallholder farmers.

- SmartFresh (USA): Uses 1-MCP to delay ripening and extend shelf life.

These technologies not only improve produce preservation but also support sustainability goals by reducing energy consumption and carbon emissions. For instance, controlled atmosphere (CA) and ultra-low oxygen (ULO) storage can extend apple shelf life up to 12 months while saving up to 50% in energy costs.

Despite the promise, the review notes that technical and economic barriers remain, especially for small-scale producers. High initial costs, complex system designs, and limited digital readiness hinder widespread adoption. The authors call for modular, open-source platforms, training programs, and policy support to make advanced cold storage technologies more accessible.

The complete study is available in open access in Food Research International.

Source

[1] Hoffmann, T. G., de Souza, C. K., Sonawane, A. D., et al. (2025). Challenges and future perspectives in postharvest cold storage: Technological review on sustainable and efficient cold storage of fresh produce. Food Research International, 117406. https://doi.org/10.1016/j.foodres.2025.117406