Technical visit to the Tokyo fish market

At the ICCC conference last June, attendees had the opportunity to participate in technical visits, including a tour of the Tokyo fish market. Alain Le Bail, President of IIR Commission C2, joined the visit and shared his insights.

‘The visit took place on a rest day, so we didn’t observe many products, apart from a few loads in progress.

The market relocated in 2017. While the old market I visited in 2004 allowed visitors to wander freely, this new, very modern market is more restricted due to hygiene reasons. For example, you can attend tuna auctions by prior registration.

The tour included a delegation of 20 peoples, three of whom were French (myself, Souhir Hammami from IIR, and Didier Pathier from Air Liquide China). An indoor presentation provided an overview of this impressive complex. The market section, which is used for post-harvest trading, is located next to the cold-storage facility, a seven-storey cubic building. A large gap (over 1 meter) separates the market from the storage area to withstand earthquakes and prevent the buildings from colliding. Japan follows specific cold chain regimes, with the following temperature ranges: +3°C for refrigerated storage; -13°C for certain products like caviar and sardines; -25°C, which is the most common storage regime; -35°C for sea urchins, shrimp, and sashimi-grade fish; and -60°C for the noblest and most prized fish among the Japanese population, such as tuna and salmon, which are also the oiliest.

At ICCC 2018 in Beijing, Prof. Manabu Watanabe, who organised this year’s congress, discussed the benefits of this temperature level for perfect fish preservation and inhibition of all oxidation phenomena. It should be noted that the -25°C regime is in the process of evolving, with regulations raising the setpoint to -18°C in order to align with international standards. We were told that this change is being implemented gradually, as the market is accustomed to -25°C. The main driver for this adjustment is energy savings.

Cold storage

During our visit to the cold storage facilities, we toured several cold rooms, with the ‘hot’ spot being the -60°C storage, which includes two large areas accounting for about 1/7 of the total storage capacity. The sizes of the rooms were impressive, as were the masses of frost on both the floor and ceiling. Access is via a fairly spacious hall where products are stored before entering the cold storage rooms.

Defrosting, which is a major task, is carried out mechanically every week for the ceilings and daily for the exchanger batteries. Battery defrosting does not apply to -60°C storage, as the air flows in an open cycle and returns to the unit with a temperature differential of approximately 10°C. Tuna are stored in bulk in metal cages, with large specimens visible.

Machine room

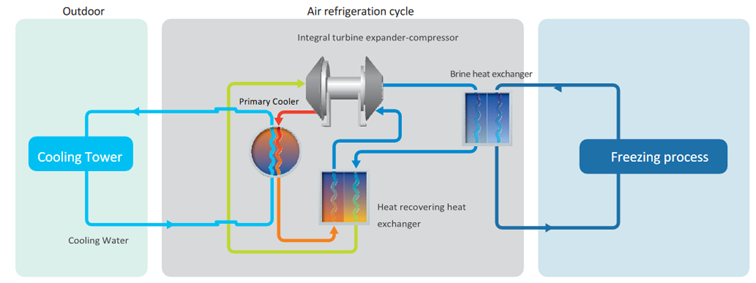

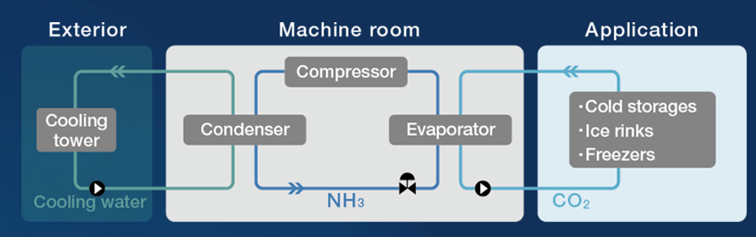

The refrigeration machines are supplied by Mayekawa, with ammonia-CO2 cascade systems up to -35°C (NewTon reference) and air-cycle machines for -60°C storage (PascalAir reference). Approximately 100 of these machines are in operation. We visited a machine room featuring two 30kW units. They operate in an open cycle on the cold side, i.e. air is injected into the cold storage rooms and then returned to the refrigeration unit. On the hot side, a water exchanger is used to ensure heat exchange. A special feature of these machines is their double turbine coupled to the fluid circulation motor – one turbine on the compression side and another on the expansion side (bootstrap). The system was started up and reached stabilised speed after 3 minutes, operating at a rotation speed of 18,000 rpm. The device was fairly quiet.

and of the expansion section under the insulators on the right

Conclusion

This visit was both very instructive and impressive. The air-cycle machines were installed in 2017 and the Mayekawa representative indicated that they have not required major maintenance since. The announced Coefficient of Performance of 0.5 seems is appealing compared to what might be expected from conventional compression systems. The technological mastering of the bootstrap and the dehydration of circulating air are critical points for these installations. These systems are designed for storage and are unlikely to be used for transport, which, according to our contacts, is managed by ‘isothermal’ systems with conventional compression refrigeration machines. Interestingly, air-cycle systems like these are also used in aeronautics for aircraft air conditioning.’

Alain Le Bail, Pres. of IIR Commission C2, ONIRIS-GEPEA Nantes, France

1 https://www.mayekawa.com.au/494/wp-content/uploads/2020/08/Pascal-Air-Brine-Cooler-Unit.pdf

2 https://mayekawa.com/lp/newton/

This article was originally published in French in issue 1191 of Revue Générale du Froid (July-August 2024), the magazine of the French Association of Refrigeration (AFF).