Thailand: refrigeration needs and energy saving measures for the dairy cold chain

Sustainable Energy for All (SEforALL) released a comprehensive overview of operational stages, energy consumption patterns, and opportunities for efficiency improvement in Thailand’s dairy cold chain, using data collected from the Thai Ministry of Commerce, the Dairy Farming Promotion Organisation of Thailand (DPO), the Ministry of Agriculture and Cooperatives, and academic research from Thai universities and local studies.

Thailand is one of the largest producer and exporter of dairy products in ASEAN, with exports estimated at over 800,000 tonnes in 2023 according to FAOstat.

In 2025, Sustainable Energy for All (SEforALL) released a comprehensive overview of the Thai dairy industry using data collected from the Thai Ministry of Commerce, the Dairy Farming Promotion Organisation of Thailand (DPO), the Ministry of Agriculture and Cooperatives, and academic research from Thai universities and local studies.

This report analyses operational stages, energy consumption patterns, and opportunities for efficiency improvement in Thailand’s dairy cold chain.

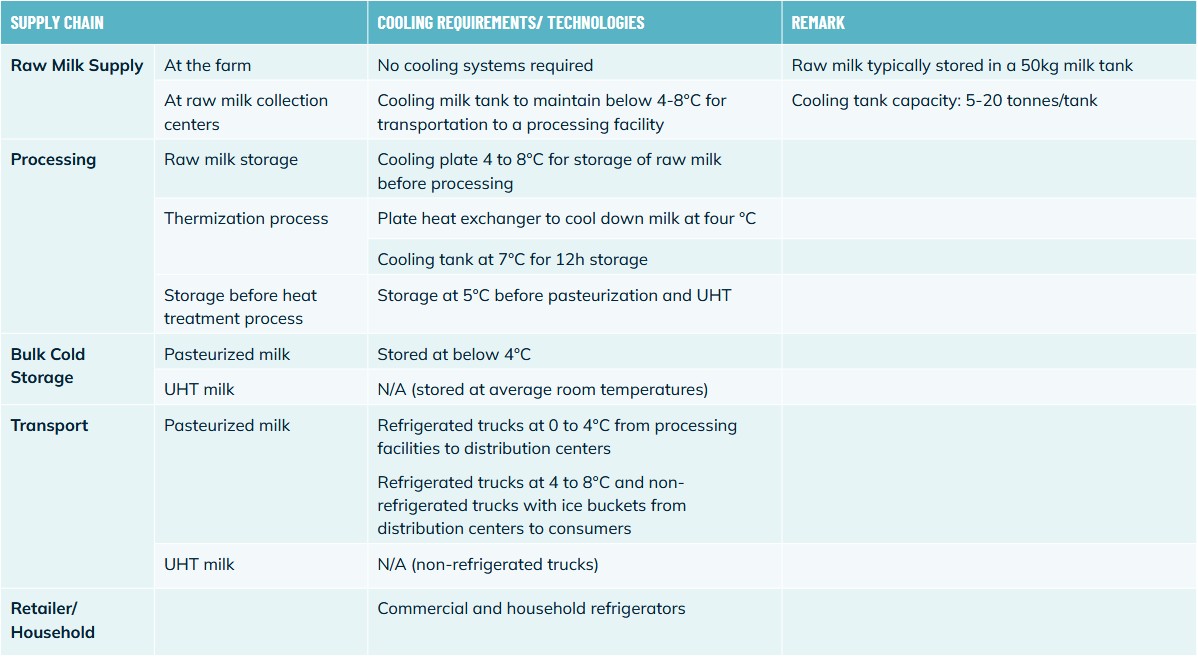

Overview of refrigeration requirements and cold chain technologies for dairy products in Thailand

Data on cold chain operations remains fragmented, limiting effective planning and monitoring. Nevertheless, Table 1 summarises typical refrigeration requirements and standard refrigeration technologies.

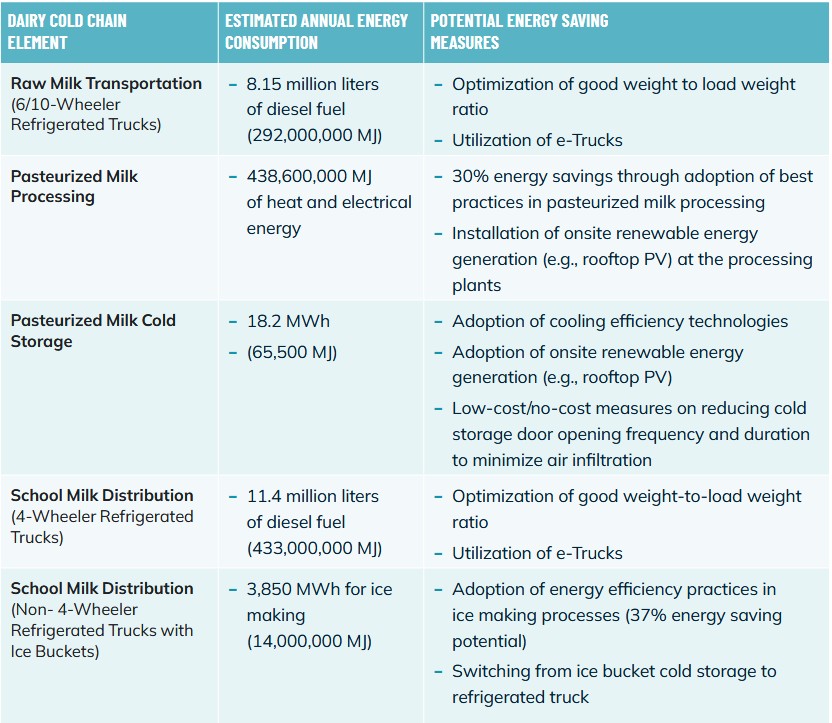

Energy consumption and potential energy-saving measures in Thai dairy cold chain

The study identifies opportunities to improve energy efficiency across Thailand’s dairy cold chain, with potential savings in transportation, processing, storage, and ice-making. For example, ice-making for non-refrigerated distribution could deliver 37 % energy savings, with further reductions possible by shifting to refrigerated vehicles.

Table 2 summarises the estimated annual energy consumption and potential energy-saving measures across key elements of the dairy cold chain in Thailand. These estimates are based on average annual production and consumption of milk drinks as well as specific energy consumption (SEC) values reported by secondary sources.

For more information, the report is available on SEforAll website.