Advances in Phase Change Materials boost efficiency of food and health cold chains

A recent article published in the International Journal of Refrigeration reviews PCMs in laboratory and commercial cold chain applications along with possible solutions to mitigate their limitations.

First, what is PCM?

Phase Change Materials (PCM) are substances that can store and release large amounts of heat when they change from one state to another, such as from solid to liquid or vice versa. They act like thermal batteries: absorbing heat when the surroundings are warm and releasing it when it cools down. PCMs are used in buildings, electronics, and textiles to regulate temperature efficiently and reduce energy consumption.

This ability to store and release heat makes PCMs particularly relevant for the cold chain, where the growing demand for the transport and storage of perishable goods requires careful temperature management. Refrigeration is essential to preserve the quality and safety of food products and temperature-sensitive health products. However, maintaining a consistent temperature throughout transportation and storage is energy- intensive. By integrating PCMs, cold chain systems can better maintain stable temperatures while reducing energy use, offering a more sustainable solution.

PCMs can effectively offer precise temperature maintenance, reusability, portability, affordability, and potential energy cost saving by recharging when electricity tariffs are low.

In a recent review article published in IIR’s International Journal of Refrigeration by a team of researchers from the Agency for Science, Technology and Research, the National University of Singapore and Nanyang Technological University, Singapore, Xiang Yun Debbie Soo and colleagues evaluated recent developments in organic, inorganic, eutectic, and polymer-gel PCM technologies. The authors examined the performance PCMs in lab-scale experimental studies as well as available commercial applications, especially for insulated cold boxes.

For instance, in an experimental study for vaccine storage, a DA-lauric acid eutectic PCM was tested with a PU and vacuum insulation panel lined box [1]. At an ambient temperature of 31 °◦C, the required temperature range of 2-8 °◦C was maintained for up to 10 hours, with uniform temperature distribution across the top, side, and bottom plates.

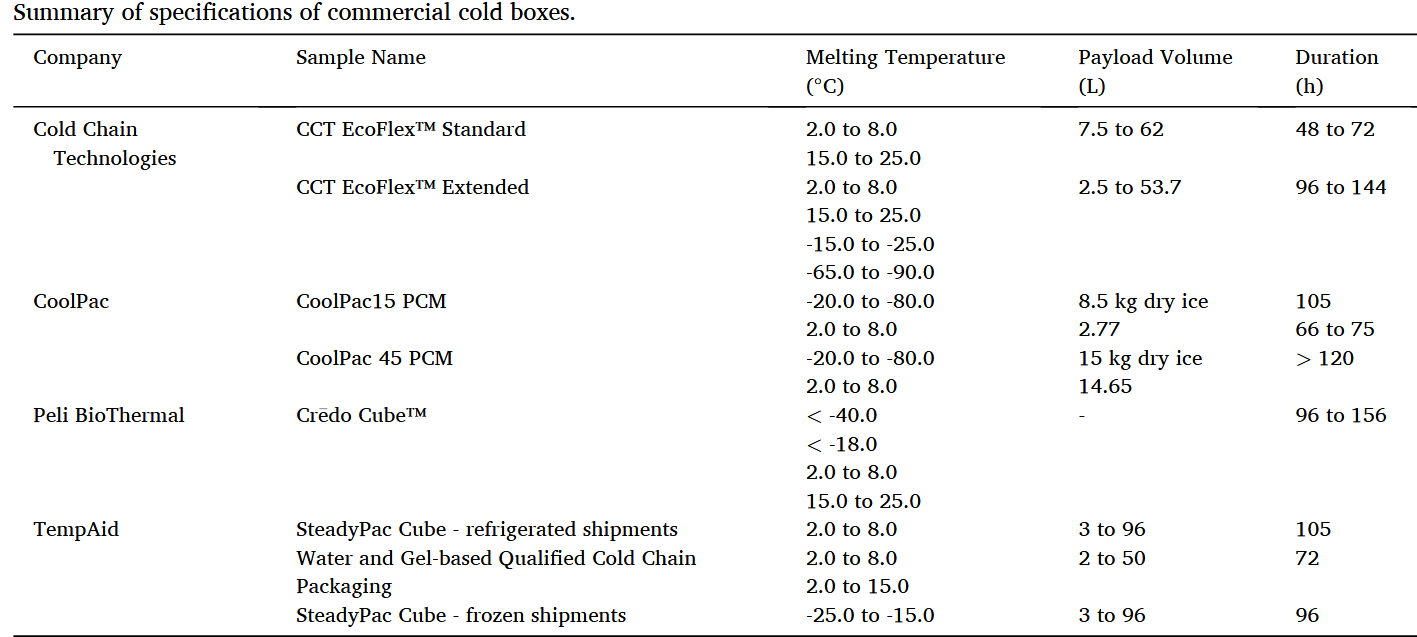

Aside from lab-scale performance, there are several commercial applications for PCMs, covering a range of working temperatures from -35 to 27°C (see table).

Despite significant advancements, research and development is ongoing to further enhance PCM formulations for improved thermal performance, longer cooling durations, and greater energy efficiency.

For instance, PCMs are prone to supercooling, meaning that they remain in their liquid state below their melting point [2]. Supercooling and phase separation can lead to a self-reinforcing degradation cycle where PCM components separate over repeated cycles, especially in salt hydrates and eutectic mixtures.

According to X.Y.D. Soo and colleagues [1], possible mitigation strategies include using nucleating agents, gelation or adsorption onto matrices to reduce supercooling, thickeners or gelling agents to reduce phase separation, conducting materials to tune thermal conductivity, and macro and microencapsulation to prevent PCM leakage during phase transitions.

The complete article is published in the International Journal of Refrigeration.

Sources

[1] Soo, X. Y. D., Ong, P. J., Lim, Y. K. Z., et al. (2025). Recent advances in low-temperature phase change materials for cold chain logistics. International Journal of Refrigeration. https://doi.org/10.1016/j.ijrefrig.2025.03.011

[2] Shamseddine, I., Pennec, F., Biwole, P., & Fardoun, F. (2022). Supercooling of phase change materials: A review. Renewable and Sustainable Energy Reviews, 158, 112172. https://doi.org/10.1016/j.rser.2022.112172

Image credits @Wikimedia