IIR Position Paper in IJR: Frozen food at −18°C or −15°C? A critical review of subzero storage, quality, and regulation

IIR expert Alain Le-Bail et al. have recently published an article reviewing the current regulations on selected subzero temperature storages and examining the impact of shifting the frozen storage temperature from −18°C to −15°C on frozen food quality.

The definition of a “frozen food” is still vague in the literature. The main consensus lies in reaching the temperature of -18°C, even though at this temperature most foods do not reach a level of frozenness (LOF) − ratio of frozen water in foods − of 100% (usually in the range of 95%). According to IIR’s “Recommendations for the Processing and Handling of Frozen Foods” (2006) [1], during a freezing process, a food product is considered as “frozen” when its temperature reaches −10°C or when 80% of the freezable water in the food has been converted into ice. In case the 80% criteria yields a temperature below -10°C, this temperature must be considered. The food must then be equilibrated at -18°C after the freezing process and must be stored at -18°C to be considered as a frozen food.

The 80% of LOF or a −10°C temperature represent a clear definition in comparison to other documents that simply indicate that the “maximal ice crystallisation zone must be passed”.

Overview of selected non-conventional below 0°C food cold chain regimes

IIR experts Alain Le-Bail, Cyril Toublanc, Michel Havet (all three members of the commission C2) and Prof Nasser Hamdami from Oniris institute in Nantes, France have published a review paper on selected non-conventional below 0°C cold chain regimes (chilling, superchilling, supercooling, stiffening for slicing) and the status and possible evolution of associated regulations [2].

Regarding “subzero” temperature storage regimes, the authors draw the following conclusions:

- The temperature of -18°C is currently considered the international standard for frozen foods. Despite this, the level of frozenness for most foods is typically in the range of 95% to 98%.

- Chilling (storage between 0°C and Initial Freezing Point temperature TIFP) is an accepted method in some European countries, such as France, and is adopted by several industries to extend the shelf life of non-frozen foods. This type of cold storage requires specific storage chambers with enhanced temperature control and is used mostly at an industrial level to gain a few days of shelf life (chilled storage).

- Superchilling (storage at a few degrees below TIFP) was adopted by the EU in 2022 for fish transport only; other applications of superchilling are not allowed in the European Union up to now. This represents a significant step forward in non-conventional frozen food storage.

- Stiffening of fish for mechanical slicing is recognised by EU regulations and the FAO/WHO’s Codex Alimentarius (Codex) as an accepted technology, provided the temperature is maintained around −10°C for up to 96 hours. CODEX standard CXC 52-2003 permits a range of −12°C to −5°C for shorter periods. However, according to food safety regulations, fish stored between its TIFP and −10°C should not be stored for extended durations due to partial freezing risks.

The impact of the “Three Degrees of Change” initiative on the shelf life of frozen foods

Based on existing data from the literature, Le-Bail et al. also examined the impact of changing the frozen food storage temperature from –18°C to –15°C, a temperature shift promoted by the “Three Degrees of Change” initiative, on the shelf life of frozen foods.

The authors draw the following conclusions:

- A shift from −18°C to −15°C for frozen food storage is expected to reduce energy consumption by approximately 10%, according to Allouche et al. (2023) [3].

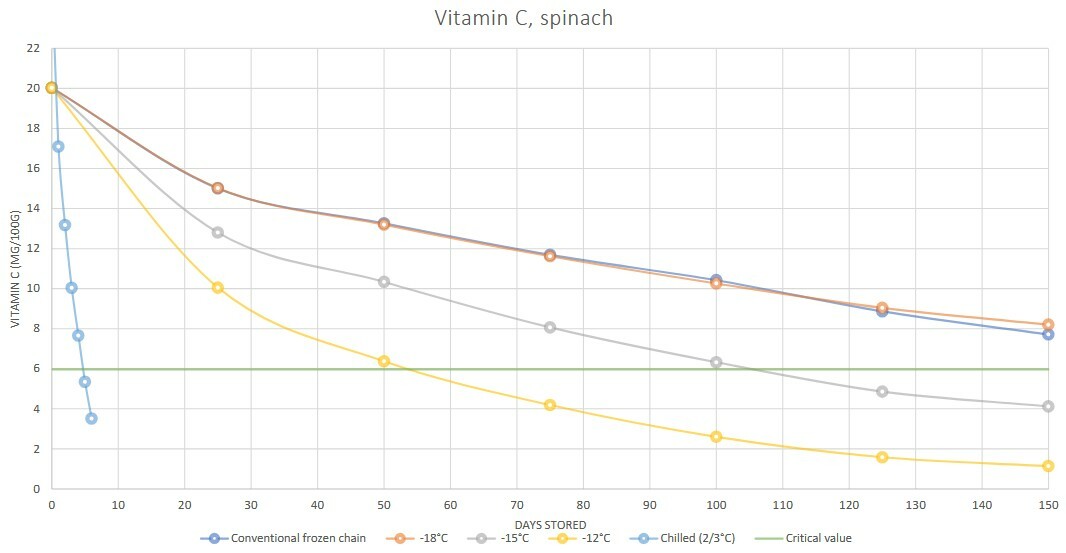

- A shift from −18°C to −15°C for frozen food storage is expected to reduce the shelf life of frozen foods with respect to quality changes (hedonic perception) by around 30%, according to 18 different studies reviewed by the authors. Allouche et al. presented a case study for spinach, showing that at -15°C, the vitamin C content decreases below critical threshold values after three months of storage (see figure 1).

- A shift from −18°C to −15°C for frozen food storage may result in restricted acceptance in terms of temperature fluctuation during frozen storage. This may require thicker packaging solutions, with the use of phase change material for example, resulting in a lower occupation ratio of food products in frozen storage and a rise in packaging weight. Also, a better control of temperature oscillation in frozen storage may be considered.

- A shift from −18°C to −15°C for frozen food storage may result in food wastage if the food industry reduces the shelf life presented on the packaging and consumers discard the food once the shelf-life date has been passed.

Specific measures may be considered to mitigate these risks. A differentiated approach could be considered as mentioned in previous publications, with for example:

- Low-sensitivity products: A 3°C increase in storage temperature with upward temperature fluctuation of 3°C could be considered.

- Medium-sensitivity products: A 3°C increase in storage temperature with upward temperature fluctuation of 1°C could be considered.

- High-sensitivity products: Current storage temperatures should be maintained to preserve quality and safety.

- The level of sensitivity could be determined based on the Q3 value and on the storage life at −18°C for example (Q3 is the ratio of a shelf life time of a food at T°C divided by the said rate at T + 3°C). By implementing these strategies, energy savings can be achieved while minimising the negative impact on product quality and food safety.

- The temperature range of −12°C to −10°C is considered a threshold below which the risk of microbial growth during storage is negligible. However, some exceptions exist, and it would be worthwhile to track the risk of microbial growth in the range between −18°C and −10°C, especially when temperature fluctuations are allowed during transport (e.g. +3°C is accepted in Europe). Virus may also be considered.

For more information, the complete study is available in open access in IIR’s International Journal of Refrigeration.

Sources

[1] IIR. Recommendations for the Processing and Handling of Frozen Foods (2006) https://iifiir.org/en/fridoc/recommendations-for-the-processing-and-handling-of-frozen-foods-4097

[2] Le-Bail A., Hamdami N., Toublanc C., Havet M. (2025). An overview of selected “subzero” temperature storage regimes of foods: regulations and perspectives about the expected impact of the “three degrees of change” initiative on the shelf life of frozen foods. International Journal of Refrigeration 176, 336–344. https://doi.org/10.1016/j.ijrefrig.2025.04.009

[3] Allouche Y., Evans J., Sayin L., Falagán N., Hetterscheid B., Peters T. (2023). Three degrees of change: frozen food in a resilient and sustainable food system, Summary Report & Initial Findings, November 2023. https://iifiir.org/en/fridoc/three-degrees-of-change-frozen-food-in-a-resilient-and-sustainable-147847