Temperature control and sustainability, the challenges of 3D meat printing

Temperature control is a key factor that still limits the application of 3D printing in the meat industry, according to recent scientific publications.

Global greenhouse gas emissions from livestock farming account for about 15% of total global emissions, according to FAO data. [1] Moreover, a study published in Nature concluded that the use of cows, pigs and other animals for food, as well as livestock feed, is responsible for 57% of all food production emissions. [2] According to a recent review article published in Current Research in Food Science, food 3D printing technology could contribute to reduce food waste and GHG emissions in the meat industry. [3] The 3D printing technology that produces cell-cultured meat eliminates the need for farming, thereby reducing land occupation and waste.

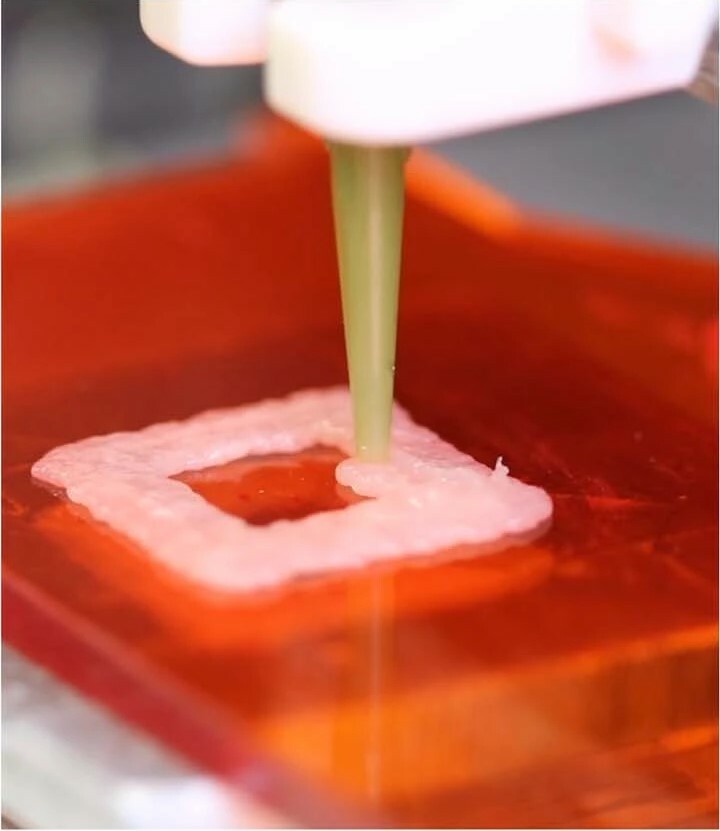

To date, the main application of food 3D printing is to customise specific shapes and achieve personalised nutrition. [4, 5] A study published in 2020 examined the use of 3D printing to develop meat products suitable for elderly people with chewing and swallowing difficulties. [5, 6] The powders or pastes used as raw materials for 3D printing can produce custom-shaped food products in a relatively short period, without complicated pre-processing or cutting. [3] However, several challenges still hinder the application of 3D printing in meat, and temperature control is one of them. [3, 4]

Temperature control is a critical requirement when printing a cultivated product containing live cells. Several studies highlight the importance of the temperature at which printing takes place, especially for complex products not intended for immediate consumption, such as meat. [4] Indeed, meat materials are complex multi-phase colloidal systems. The unique fibrous structure of meat adds to the challenge of printing, thus requiring pre-treatment or additives to allow the ink to extrude smoothly from the nozzle and maintain good self-support and formability. Lower temperatures facilitate the process, since the difference in temperature between the nozzle and the plate of the printer can be beneficial for setting the first layers deposited. However, there will be a marked thermal gradient between layers (several degrees Celsius over a few millimetres). Therefore, the cooling effect of the plate will become limited. [4]

Furthermore, the risk of bacterial contamination is also an important factor when considering a cooling system. [4] For example, microbial growth can be inhibited, and spoilage of meat products can be prevented during printing by always setting a printing temperature of less than 4°C. However, cooling during printing results in energy consumption, thus deteriorating the sustainability in large-scale food production. [3] Therefore, the development of energy-efficient and environmentally friendly temperature-controlled automatic 3D printers can provide a basis for the commercialisation of food 3D printing.

Did you know? The IIR has released two summary documents on additive manufacturing of refrigeration components, prepared with Kristina Navickaite, junior member of the E1 Commission on “Air Conditioning”.

Additive manufacturing of heat exchangers

Sources

[1] https://www.fao.org/news/story/en/item/197608/icode/

[2] Xu, X., Sharma, P., Shu, S. et al. Global greenhouse gas emissions from animal-based foods are twice those of plant-based foods. Nat Food 2, 724–732 (2021). https://doi.org/10.1038/s43016-021-00358-x

[3] Dong, H., Wang, P., Yang, Z., & Xu, X. (2022). 3D printing based on meat materials: Challenges and opportunities. Current Research in Food Science, 100423. https://doi.org/10.1016/j.crfs.2022.100423

[4] Portanguen, S., Tournayre, P., Sicard, J., Astruc, T., & Mirade, P. S. (2022). 3D food printing: Genesis, trends and prospects. In Future Foods (pp. 627-644). Academic Press. https://doi.org/10.1016/B978-0-323-91001-9.00008-6

[5] Yang, G., Tao, Y., Wang, P., Xu, X., & Zhu, X. (2022). Optimizing 3D printing of chicken meat by response surface methodology and genetic algorithm: Feasibility study of 3D printed chicken product. LWT, 154, 112693. https://doi.org/10.1016/j.lwt.2021.112693

[6] Dick, A., Bhandari, B., Dong, X., & Prakash, S. (2020). Feasibility study of hydrocolloid incorporated 3D printed pork as dysphagia food. Food Hydrocolloids, 107, 105940. https://doi.org/10.1016/j.foodhyd.2020.105940

[7] Blutinger, J.D., Tsai, A., Storvick, E. et al. Precision cooking for printed foods via multiwavelength lasers. npj Sci Food 5, 24 (2021). https://doi.org/10.1038/s41538-021-00107-1

Credits image: Pete Linforth de Pixabay