Ice cream manufacturing, environmental impact and market data

From a physico-chemical point of view, ice cream is a complex, frozen multiphase mixture. The manufacturing process includes several stages of freezing which are described in this summary document. Given that the global ice cream industry is worth over 80 billion USD, the economic data and the environmental impact of the sector are also presented.

Physico-chemical structure of ice cream

According to the European Code for edible ices, the term “ice cream” is reserved for a product which (i) complies with the basic definition of edible ices (e.g. foodstuffs frozen from a liquid state to a more viscous texture and which are stored, transported, sold and consumed in a frozen state); and (ii) is an emulsion typically composed of water and/or milk, edible fats, proteins and sugars.[1]

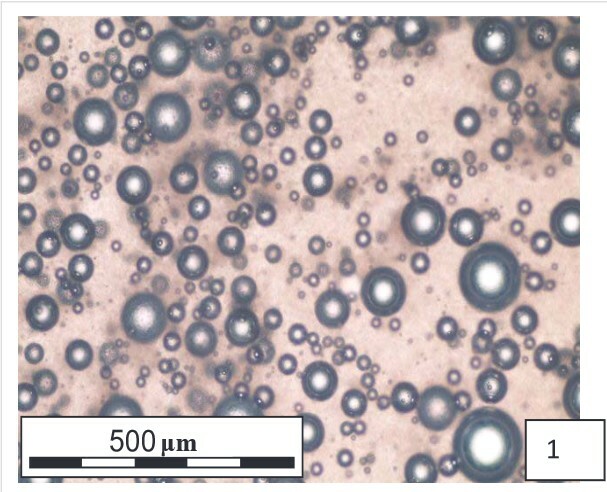

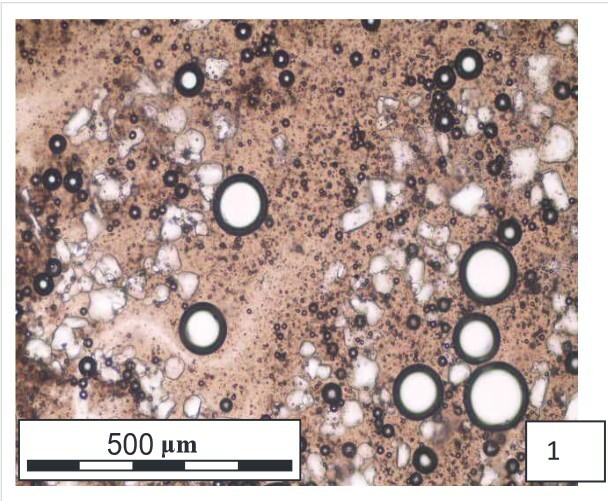

From a physico-chemical point of view, ice cream can be considered at the same time as an emulsion, a dispersion, and a foam.[2] The dispersion and emulsion consist primarily of a freeze-concentrated aqueous serum phase containing sugar and dry matter surrounding dispersed ice crystals and fat globules. The foam is formed by air pockets dispersed throughout the emulsion and is supported by partially-coalesced fat globules.[3] Ice cream can therefore be defined as a complex food matrix consisting of a frozen multiphase mixture containing ice crystals, air bubbles and partially coalesced fat globules in an unfrozen serum phase.[4]

These structures affect the product quality and shelf life.[2] For instance, crystal size is widely recognized as a critical factor in the development of a smooth and creamy texture desired by consumers.[5]

|

|

Freezing stages in ice cream manufacturing

Despite the great variety of ice cream and edible ice products, the manufacturing process for most of these products typically involves the following steps:[8]

- Preparation of a liquid mixture of ingredients

- Pasteurisation of the mixture to destroy pathogenic bacteria

- Homogenisation to ensure individual fat globules are about 1 µm

- Ageing of the mixture which helps to improve whipping qualities as well as body and texture of ice cream [9]

- Dynamic freezing of the mixture to a soft, semi-frozen slurry

- Incorporation of flavouring ingredients into the partially frozen mixture

- Packaging or shaping of the product

- Further freezing (hardening) of the product.

Typically, there are two stages of freezing in ice cream manufacturing: dynamic freezing and hardening.

First freezing step: dynamic freezing

During initial freezing, which occurs at around −5°C, about half of the water in the homogenised mixture of ingredients is frozen rapidly, and air is also incorporated into the product.[5] Ice cream structures (e.g., ice crystals, air cells, clustered fat globules) are formed during this dynamic freezing step. Inclusions or particulates (e.g., chocolate chips, nuts, fruits) and variegates (e.g., caramel, marshmallow) may then be added. Afterwards, the ice cream slurry, at about −6°C, is packed into its retail container.[3,10]

The dynamic freezing step is carried out in a scraped-surface freezer (SSF) in batch or continuous mode.[11] Continuous freezers dominate the medium- to large-scale processing industry, while batch freezers are limited to small-scale processors, retailers, including restaurants, and product development applications.[8]

In a typical SSF, the mixture is rapidly cooled against the wall of a highly chilled cylindrical barrel. Ice crystals nucleate and grow on, or close to, the wall and potentially into an undercooled liquid. Rotating scraper blades break up the initially formed crystals and sweep them into the bulk of the mixture (where the mean temperature is closer to -4°C to -6°C), causing the initial ice crystals to fragment and partially melt.[11]

Second freezing step: ice cream hardening

After packaging comes the second stage of freezing, also called hardening. The ice cream containers are placed in an air blast freezer for hardening until the core temperature of the mixture reaches about −18°C. This can take about two hours at a cooling rate of ~0.1°C/min.[5] During this step, the previously formed ice crystals grow as the temperature decreases.[12] For the second freezing step, forced-air convection freezers, such as air blast tunnels, or plate-type conduction freezers are used to reduce the internal temperature to −25 to −30°C.[8]

The final product is stored at temperatures ranging from −23 to −18°C before being distributed to the consumer.[5]

Recommendations for ice cream storage and shelf life

Ice cream should be kept cold with minimal temperature fluctuations throughout the cold chain, from factory cold store to the retailer cold store and the shop freezer. [13] Any fluctuation in storage temperature causes ice crystals to melt and reform, resulting in a coarser, more icy texture of the product, which reduces its consumer appeal. The extreme sensitivity of ice cream to high temperatures and to fluctuations in temperatures makes it more sensitive to poor transport conditions than most other frozen foods.[14]

- During transportation, the temperature should be −20°C or preferably lower.[14]

- At the point of sale, several sources agree that a temperature of −18°C should not be exceeded.[14–17]

- At home, according to the International Dairy Foods Association (IDFA), ice cream should be stored in the main part of the household freezer, which should be set at a temperature between −20°C and −18°C. The IDFA recommends not allowing ice cream to soften and re-freeze repeatedly.[17]

Ice cream shelf life

Shelf life refers to the length of time a food product can be kept in storage before it loses its physical, chemical or sensory characteristics to the point of becoming unfit for sale.[18] Researchers have attempted to assess the shelf life of ice cream using accelerated testing.[18] According to studies, the shelf life of ice cream can range from several months to a few days depending on temperature.[18,19] The shelf life limitations of ice cream are mostly related to ice recrystallisation or other structural rearrangements that lead to structural or textural defects.[19]

According to IIR recommendations for frozen foods, ice cream can be stored at -24°C for 2 years, -18°C for 6 months and -12°C for 1 month.[14]

Microbial quality of ice cream and food safety

The frozen state generally prevents the growth of organisms that may affect the quality of the ice cream. Microbial growth may be a concern during the intensive processing after the pasteurisation step. Foodborne pathogens may contaminate ice cream after heat treatment from working environments or through the addition of contaminated ingredients.

However, overall, only a few outbreaks of foodborne illnesses related to ice cream consumption have been recorded.[4] Several hygiene standards apply when processing foodstuffs, or processing animal products used to prepare edible ices.[1,20]

The global ice cream market

In 2021, the global ice cream market was estimated to be around USD 70-80 billion, and is expected to reach around USD 90-100 billion in the next five years.[21,22]

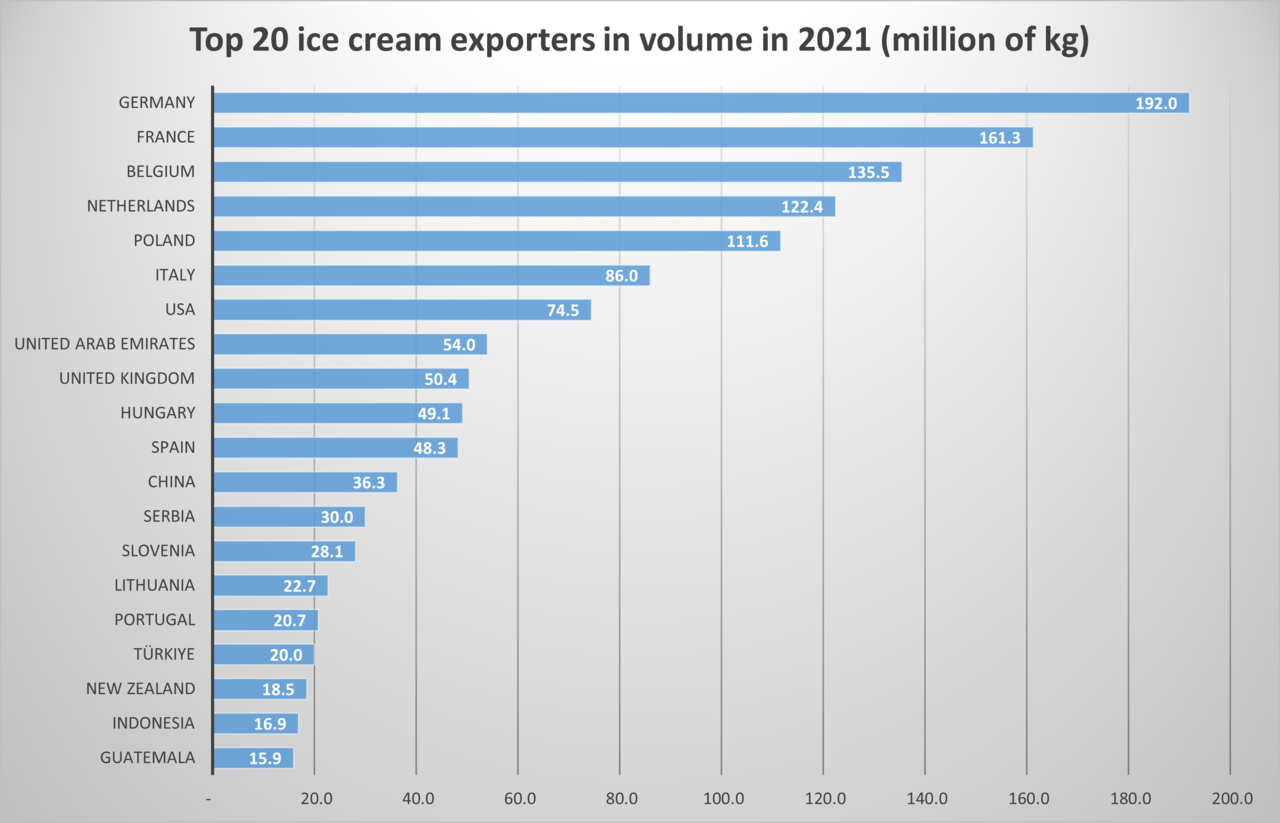

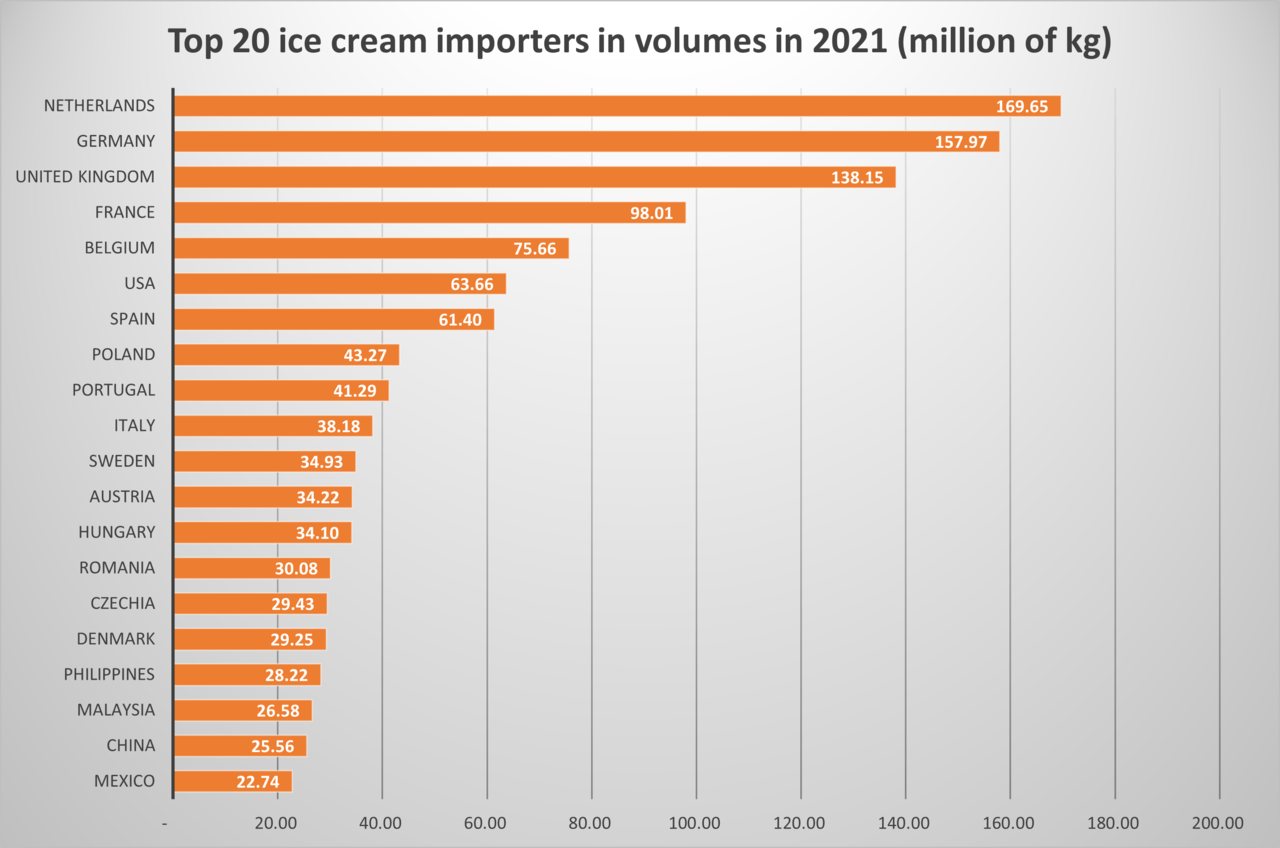

According to data from the United Nations COMTRADE database, Europe dominates the global ice cream trade, both in exports and imports. In 2021, Germany was the largest exporter of ice cream, followed by France, Belgium and the Netherlands. The United States was the 7th largest exporter of ice cream in the world and China the 12th.[23,24]

In 2021, 4.9 billion litres of ice cream were produced in the United States[21] and over 3.1 billion litres in the E.U.[25] In 2021, Germany was the main producer of ice cream among the EU Member States, producing 614 million litres of ice cream. Germany was followed by France (459 million litres) and Italy (381 million litres).[25]

According to market research analysts, Asia-Pacific is expected to witness a high growth rate, owing to a rise in demand from emerging economies such as India, China, Indonesia, and others. The LAMEA (Latin America, Middle East and Africa) region is also expected to show significant growth over the forecast period, owing to the rising demand for ice cream from younger demographics and emerging middle class. The LAMEA region accounted for one-sixth of the global ice cream market in 2020, and Brazil accounted for approximately half of the LAMEA ice cream market share.[26]

Environmental impact of the ice cream industry

Energy consumption and CO2 emissions

A team of UK researchers conducted a comprehensive life cycle assessment of ice cream, using market-leading vanilla and chocolate ice creams as case studies. Based on the annual UK consumption of ice cream of 404 kt, it was estimated that the sector consumes around 17.3 PJ of primary energy per year and emits 1.6 Mt CO2 eq., therefore accounting for 1.8% of the GHG emissions from the entire food and drink sector in the UK.[27]

They found that the overall environmental impacts of ice cream were mainly due to the ingredients, while the impacts from the manufacturing process were mostly attributable to energy consumption, particularly from the hardening and storage processes. The calculated impacts were influenced by storage time at the manufacturer and retailer, as well as the type of refrigerant used. For instance, decreasing the storage time at the manufacturer from the baseline of 30 days to 15 days reduced the energy demand by 5%.[27]

Environmental impact of refrigerants used in ice cream manufacturing and retail

Ammonia has been used for a long time and is the most common refrigerant used in large-scale ice cream operations.[12]

HFC R404A is also very common in ice cream manufacturing, despite its high GWP of 4200. The authors of a study on ice cream viscosity described a scraped-surface batch freezer. The freezer consisted of a jacketed cylindrical tank with a capacity of 500 mL. This tank was coupled to a primary cooling system using R404A refrigerant and a secondary cooling bath using ethylene glycol. This system could reach a bath temperature of about −30°C. The cooled ethylene glycol circulated inside the freezer jacket. During the crystallisation process, the energy consumption gradually increased as the temperature of the semi-frozen phase decreased. The authors observed that the energy increase in the power consumed by the stirring motor of the freezer was proportional to the increase in the fraction of crystals formed, and therefore related to the increase in the viscosity of the ice cream which determines its quality.[2]

Given the high GWP of R404A, alternative refrigerants are needed in ice cream manufacturing. For example, a R290/DME (propane/dimethyl ether) mixture was tested in one study. The author found that ice cream formation time was shorter and the COP was higher than that of a R404A system.[28] In the UK, an ice cream company recently installed an energy-efficient freezing technology using CO2 as a refrigerant.[29]

At the retail stage, the most common HFCs used in existing food retail and food service operations, according to UNEP, are R404A and R134a (GWP 1360).[30] Stand-alone commercial systems have mostly switched to R290 (GWP <1).[30] The authors of the life cycle assessment of the UK ice cream industry compared the impacts of R134a, R152a and ammonia at the retail stage. They found that using R152a or ammonia would decrease ozone depletion potential by up to 95%. R152a would also reduce global warming potential by 1.1%. The authors suggested that reducing storage time along with using refrigerants with low ozone depletion and global warming potentials should help reduce the environmental impacts of the ice cream industry.[27]

Useful links for further information

-

IIR publication

Bogh-Sorensen, L., & IIF-IIR. (2006). Recommendations for the processing and handling of frozen foods. International Institute of Refrigeration.

https://iifiir.org/en/fridoc/recommendations-for-the-processing-and-handling-of-frozen-foods-4097 -

Articles from the International Journal of Refrigeration

Parra, O. D. H., Ndoye, F. T., Benkhelifa, H., Flick, D., & Alvarez, G. (2018). Effect of process parameters on ice crystals and air bubbles size distributions of sorbets in a scraped surface heat exchanger. International Journal of Refrigeration, 92, 225-234. https://iifiir.org/en/fridoc/effect-of-process-parameters-on-ice-crystals-and-air-bubbles-size-141389

Leducq, D., Ndoye, F. T., & Alvarez, G. (2015). Phase change material for the thermal protection of ice cream during storage and transportation. International Journal of Refrigeration, 52, 133-139. https://iifiir.org/en/fridoc/phase-change-material-for-the-thermal-protection-of-ice-cream-during-138332

-

Conference papers

Masselot V., Bosc V., Benkhelifa H. (2019) Characterization of sorbet microstructure by using X-Ray microtomography. Proceedings of the 25th IIR International Congress of Refrigeration: Montréal , Canada, August 24-30, 2019. https://iifiir.org/en/fridoc/characterization-of-sorbet-microstructure-by-using-x-ray-microtomography-34942

-

Open access articles

Tvorogova, A., Shobanova, T., Landikhovskaya, A., Sitnikova, P., & Gurskiy, I. (2020). Nucleation Intensification in the Ice Cream Production. Eastern-European Journal of Enterprise Technologies, 2(11), 104. https://iifiir.org/en/fridoc/nucleation-intensification-in-the-ice-cream-production-145648

Sitnikova, P. B., & Tvorogova, A. A. (2019). Physical changes in the structure of ice cream and frozen fruit desserts during storage. Food systems, 2(2), 31-35. https://iifiir.org/en/fridoc/physical-changes-in-the-structure-of-ice-cream-and-frozen-fruit-145893

Konstantas, A., Stamford, L., & Azapagic, A. (2019). Environmental impacts of ice cream. Journal of Cleaner Production, 209, 259–272. https://doi.org/10.1016/j.jclepro.2018.10.237

Acknowledgements

This summary document was prepared by Monique Baha (IIR head office), revised by Dr. Antonina Tvorogova (member of the C2 commission on “Food science & engineering”), Pr Adisa Azapagic (University of Manchester) and Dr Laurence Stamford (University of Manchester). It was proofread by Nathalie de Grissac and Zoé Martin, under the supervision of Jean-Luc Dupont (Head of the Scientific and Technical Information Department).

References

[1] European Ice Cream Association. (2017, November 22). Code for Edible Ices, version 2013. EuroGlaces. https://www.euroglaces.eu/code-edible-ices

[2] De la Cruz Martínez, A., Delgado Portales, R. E., Pérez Martínez, J. D., González Ramírez, J. E., Villalobos Lara, A. D., Borras Enríquez, A. J., & Moscosa Santillán, M. (2020). Estimation of Ice Cream Mixture Viscosity during Batch Crystallization in a Scraped Surface Heat Exchanger. Processes, 8(2), 167. https://doi.org/10.3390/pr8020167

[3] Cook, K. L. K., & Hartel, R. W. (2010). Mechanisms of Ice Crystallization in Ice Cream Production. Comprehensive Reviews in Food Science and Food Safety, 9(2), 213–222. https://doi.org/10.1111/j.1541-4337.2009.00101.x

[4] Nalbone, L., Vallone, L., Giarratana, F., Virgone, G., Lamberta, F., Marotta, S. M., Donato, G., Giuffrida, A., & Ziino, G. (2022). Microbial Risk Assessment of Industrial Ice Cream Marketed in Italy. Applied Sciences, 12(4), 1988. https://doi.org/10.3390/app12041988

[5] Mo, J., Groot, R. D., McCartney, G., Guo, E., Bent, J., van Dalen, G., Schuetz, P., Rockett, P., & Lee, P. D. (2019). Ice Crystal Coarsening in Ice Cream during Cooling: A Comparison of Theory and Experiment. Crystals, 9(6), 321. https://doi.org/10.3390/cryst9060321

[6] Sitnikova, P. B., & Tvorogova, A. A. (2019). Physical changes in the structure of ice cream and frozen fruit desserts during storage. Food Systems, 2(2), 31–35. https://doi.org/10.21323/2618-9771-2019-2-2-31-35

[7] Scarborough college. (2010, June 6). IB Group 4 " Ice-cream project ": Practical 4 - Investigating the fat and air content of the ice cream under a microscope. IB Group 4 " Ice-Cream Project ". http://g4icecreamproject.blogspot.com/2013/06/practical-4-investigating-fat-and-air.html

[8] Goff, H. D., & Hartel, R. W. (2013). Chapter 1—The Ice Cream Industry. In H. D. Goff & R. W. Hartel (Eds.), Ice Cream (pp. 1–17). Springer US. https://doi.org/10.1007/978-1-4614-6096-1_1

[9] Goff, H. D. (2021). Ageing of Mix. In Ice Cream Technology eBook (University of Guelph). https://books.lib.uoguelph.ca/icecreamtechnologyebook/chapter/ageing-of-mix/

[10] Hartel, R. (2019). Engineering Frozen Desserts. Chemical Engineering Progress, 115(5), 39–43. https://www.aiche.org/resources/publications/cep/2019/may/engineering-frozen-desserts

[11] Mo, J., Guo, E., McCartney, D. G., Eastwood, D. S., Bent, J., Van Dalen, G., Schuetz, P., Rockett, P., & Lee, P. D. (2018). Time-Resolved Tomographic Quantification of the Microstructural Evolution of Ice Cream. Materials, 11(10), 2031. https://doi.org/10.3390/ma11102031

[12] Goff, H. D., & Hartel, R. W. (2013). Chapter 7—Freezing and Refrigeration. In H. D. Goff & R. W. Hartel (Eds.), Ice Cream (pp. 193–248). Springer US. https://doi.org/10.1007/978-1-4614-6096-1_7

[13] European Ice Cream Association. (2017, November 22). Ice Cream Storage. EuroGlaces. https://www.euroglaces.eu/ice-cream-storage

[14] Bogh-Sorensen, L., & IIF-IIR. (2006). Recommendations for the processing and handling of frozen foods. International Institute of Refrigeration. https://iifiir.org/en/fridoc/recommendations-for-the-processing-and-handling-of-frozen-foods-4097

[15] British Frozen Food Federation (BFFF). (2017). Guide to the storage and handling of frozen foods. BFFF (British Frozen Food Federation). https://bfff.co.uk/wp-content/uploads/2013/06/2017-Gold-Book.pdf

[16] Direction générale de la concurrence, de la consommation et de la répression des fraudes (DGCCRF). (2021, July 12). Glaces, sorbets et crèmes glacées: Comment les conserver ? https://www.economie.gouv.fr/dgccrf/Publications/Vie-pratique/Fiches-pratiques/Glaces-cremes-glacees-sorbets

[17] IDFA - International Dairy Foods Association. Tips on Storing & Handling Ice Cream. IDFA. Retrieved 4 May 2022, from https://www.idfa.org/tips-on-storing-handling-ice-cream

[18] Park, J.-M., Koh, J.-H., & Kim, J.-M. (2018). Predicting Shelf-life of Ice Cream by Accelerated Conditions. Korean Journal for Food Science of Animal Resources, 38(6), 1216–1225. https://doi.org/10.5851/kosfa.2018.e55

[19] Goff, H. D., & Hartel, R. W. (2013). Chapter 12—Shelf Life. In H. D. Goff & R. W. Hartel (Eds.), Ice Cream (pp. 353–378). Springer US. https://doi.org/10.1007/978-1-4614-6096-1_12

[20] Goff, H. D., & Hartel, R. W. (2013). Chapter 13—Cleaning and Sanitizing for Microbiological Quality and Safety. In H. D. Goff & R. W. Hartel (Eds.), Ice Cream (pp. 379–401). Springer US. https://doi.org/10.1007/978-1-4614-6096-1_13

[21] IDFA - International Dairy Foods Association. (2022). Ice Cream Sales & Trends. IDFA. https://www.idfa.org/ice-cream-sales-trends

[22] Ministry for Primary Industries. (2022, February). New Zealand ice cream trade. https://www.mpi.govt.nz/dmsdocument/42357/direct

[23] OEC - The Observatory of Economic Complexity. (2020). World trade of ice cream and other edible ice. OEC - The Observatory of Economic Complexity. https://oec.world/en/profile/hs/ice-cream-and-other-edible-ice

[24] United Nations. (2022). UN Comtrade: International Trade Statistics. https://comtradeplus.un.org/TradeFlow

[25] Eurostat. (2022, August 29). Where does your ice cream come from? https://ec.europa.eu/eurostat/web/products-eurostat-news/-/edn-20220829-1

[26] Allied Market Research. (2022). Ice Cream Market Size, Share & Trends. Analysis Forecast 2031. Allied Market Research. https://www.alliedmarketresearch.com/ice-cream-market

[27] Konstantas, A., Stamford, L., & Azapagic, A. (2019). Environmental impacts of ice cream. Journal of Cleaner Production, 209, 259–272. https://doi.org/10.1016/j.jclepro.2018.10.237

[28] Kim, N.-H. (2016). Application of the Natural Refrigerant Mixture R-290/DME to a Soft Ice Cream Refrigerator. International Journal of Air-Conditioning and Refrigeration, 24(04), 1650027. https://doi.org/10.1142/S2010132516500279

[29] Starfrost Ltd (UK). (2021, August 3). Starfrost Helix spiral freezer delivers energy efficiency benefits at Mackie’s of Scotland. British Frozen Food Federation (BFFF). https://bfff.co.uk/starfrost-helix-spiral-freezer-deliveres-energy-efficiency-benefits-at-mackies-of-scotland/

[30] UNEP. (2021). Refrigeration, Air Conditioning and Heat Pumps TOC (RTOC) Progress Report. In Technology and Economic Assessment Panel (TEAP) 2021. Progress Report (Volume 1). https://ozone.unep.org/node/11983

Search in the encyclopedia for articles on the following topics:

Cryogenics and gas processing | Refrigerants and secondary refrigerants | Refrigerating equipment | Cryobiology and cryomedicine, freeze-drying | Application of refrigeration to perishable products | Refrigerated storage | Heat pumps, energy recovery | General information on refrigeration, energy and environment